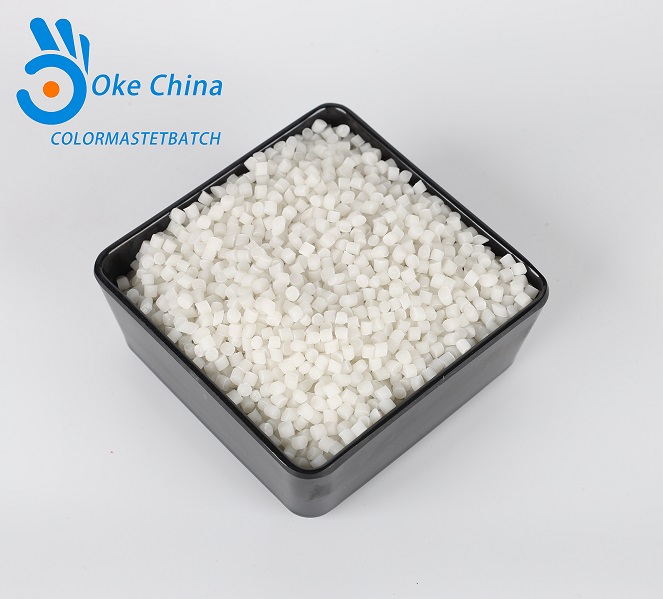

Introduction to Calcium Carbonate (CaCO₃) PE Filler Masterbatch

Calcium carbonate PE filler masterbatch is a functional masterbatch composed of polyethylene (PE) as the carrier resin, calcium carbonate (CaCO₃) as the primary filler, and additives such as dispersants and coupling agents. It is widely used in the plastics processing industry to reduce production costs, improve product performance, and impart certain functional properties to materials.

1. Basic Composition

Component | Function | Typical Proportion |

Polyethylene (PE) | Carrier resin, provides melt flowability | 20%~40% |

Calcium Carbonate (CaCO₃) | Main filler, reduces cost, enhances rigidity | 60%~80% |

Coupling Agent (e.g., titanate, silane) | Improves compatibility between CaCO₃ and PE | 0.5%~2% |

Dispersant (e.g., PE wax) | Prevents CaCO₃ agglomeration, enhances dispersion | 1%~3% |

Lubricant (e.g., stearic acid) | Improves processing flowability | 0.5%~1% |

2. Key Characteristics

✅ Cost Reduction: CaCO₃ is significantly cheaper than PE, greatly lowering raw material costs.

✅ Increased Rigidity: Enhances hardness and compressive strength while reducing warpage.

✅ Improved Processability: Boosts melt flowability, reduces shrinkage, and facilitates injection molding/extrusion.

✅ Eco-Friendliness: Some biodegradable-modified PE masterbatches can be used in sustainable packaging.

❌ Drawbacks:

● Excessive addition (>30%) may reduce toughness and impact strength.

● Untreated CaCO₃ may lead to poor dispersion, affecting surface gloss.

3. Application Fields

Industry | Typical Applications |

Packaging | Shopping bags, garbage bags, packaging films (cost reduction, enhanced stiffness) |

Pipes/Profiles | PE water pipes, construction templates (improved rigidity, reduced shrinkage) |

Injection-Molded Products | Plastic buckets, storage bins, daily necessities (cost reduction, better dimensional stability) |

Films/Agricultural Films | Mulch films, industrial stretch films (cost reduction, increased tensile strength) |

Eco-Friendly Materials | Biodegradable PLA/CaCO₃ composite masterbatches (for bio-based packaging) |

4. Impact of Calcium Carbonate Type on Performance

Type | Characteristics | Suitable Applications |

Ground Calcium Carbonate (GCC) | Mined from limestone, low cost, larger particle size (1~10μm) | General filling, e.g., garbage bags, low-end pipes |

Precipitated Calcium Carbonate (PCC) | Chemically synthesized, finer particles (0.1~1μm), better dispersion | High-end films, injection-molded parts (smoother surface) |

Nano Calcium Carbonate | Particle size <100nm, significant reinforcement, but higher cost | High-strength engineering plastics, automotive parts |

5. Key Production Technologies

Surface Modification:

Use of titanate or silane coupling agents to enhance interfacial bonding between CaCO₃ and PE.

Reduces agglomeration, allowing higher filler content (up to 80%).

High-Shear Mixing:

Twin-screw extrusion granulation ensures uniform CaCO₃ dispersion.

Lubrication System Optimization:

Addition of PE wax, stearic acid, etc., prevents sticking during processing.

7. Usage Recommendations

Dosage: Typically 5%~30% (excessive amounts may reduce toughness).

Processing Temperature: 160~220°C (compatible with PE base resin).

Suitable Equipment: Injection molding machines, blown film lines, extruders, etc.

Conclusion

Calcium carbonate PE filler masterbatch is a cost-effective and high-performance plastic modification material that reduces costs, enhances rigidity, and improves processability, making it widely applicable in packaging, pipes, films, and other fields. Selecting the appropriate CaCO₃ type and optimizing surface modification and dispersion processes are crucial. In the future, advancements in nano-CaCO₃ and biodegradable PLA/CaCO₃ composite masterbatches will drive its adoption in more high-end and eco-friendly applications.