Why Must Color Masterbatches Be Matched to Samples for Color Tuning?

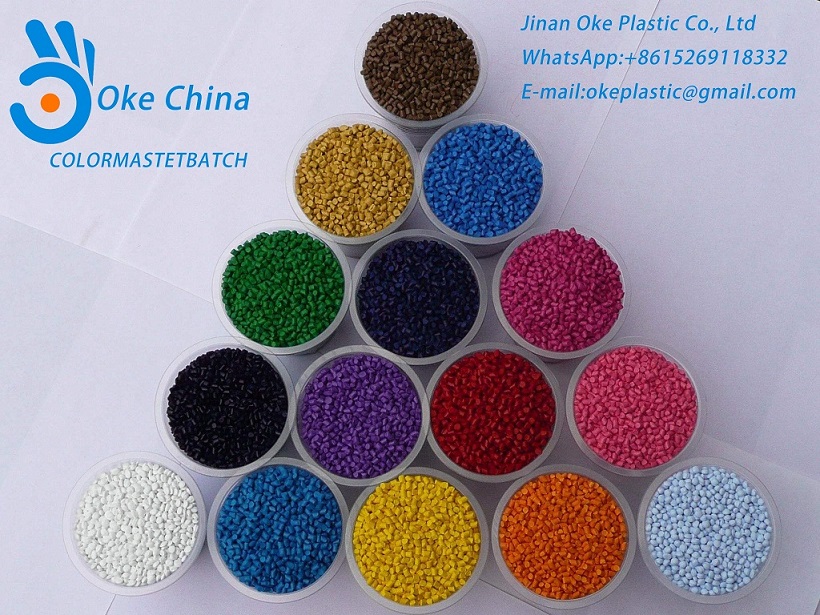

Color masterbatches must be adjusted based on physical samples for the following key reasons:

1. Precision in Color Matching

● Different industries (e.g., plastic products, textiles, packaging) have strict color requirements, especially for brand-specific or design-specific shades. The human eye is highly sensitive to color variations, and even slight deviations (e.g., a reddish or bluish tint) can lead to product rejection.

● Example: Coca-Cola’s "Classic Red" or Tiffany’s "Robin Egg Blue" must be perfectly consistent to maintain brand identity.

2. Material and Processing Effects

● Substrate Differences: The same masterbatch may appear differently in various plastics (e.g., PP, ABS, PET) due to differences in transparency or crystallinity. For instance, a pigment may look brighter in transparent PET than in white ABS.

● Processing Conditions: Factors like injection molding temperature and extrusion speed can alter color (e.g., high temperatures may degrade organic pigments, causing darkening).

3. Pigment/Dye Characteristics

● Different pigment systems have varying color gamuts (e.g., inorganic pigments are duller, organic pigments are more vibrant). Special effects (pearlescent, fluorescent) require specific formulations.

● Opacity Issues: Dark masterbatches may show through in thin-walled products, requiring adjustments in concentration or TiO₂ addition.

4. Batch Consistency & Standardization

● Sample-based tuning establishes a standardized formula (e.g., Pantone reference + resin ratio) to ensure color uniformity in mass production. Uncalibrated masterbatches can cause noticeable batch-to-batch variations (ΔE > 1.5 is visibly detectable).

5. Complexity of Optical Effects

● Surface finish (glossy/matte) affects color perception. For example, the same masterbatch may appear darker on a matte film than on a glossy molded part, requiring pre-adjustment.

Key Steps in Color Matching Process:

1、Spectrophotometer Analysis: Measures sample L*a*b* values for quantitative color data.

2、Substrate Simulation Tests: Trials in actual production plastics to avoid lab-to-factory discrepancies.

3、Weathering Tests: UV resistance checks for outdoor applications.

Exceptions

● Standard color charts (e.g., RAL or Pantone) may be used directly only if the client accepts them without specifying substrate/process conditions. However, exact matches are rare in practice.

In summary, color tuning is a multidisciplinary process balancing color theory, material science, and manufacturing technology. Physical samples are the only reliable reference—skipping this step risks costly rework.