Product Introduction

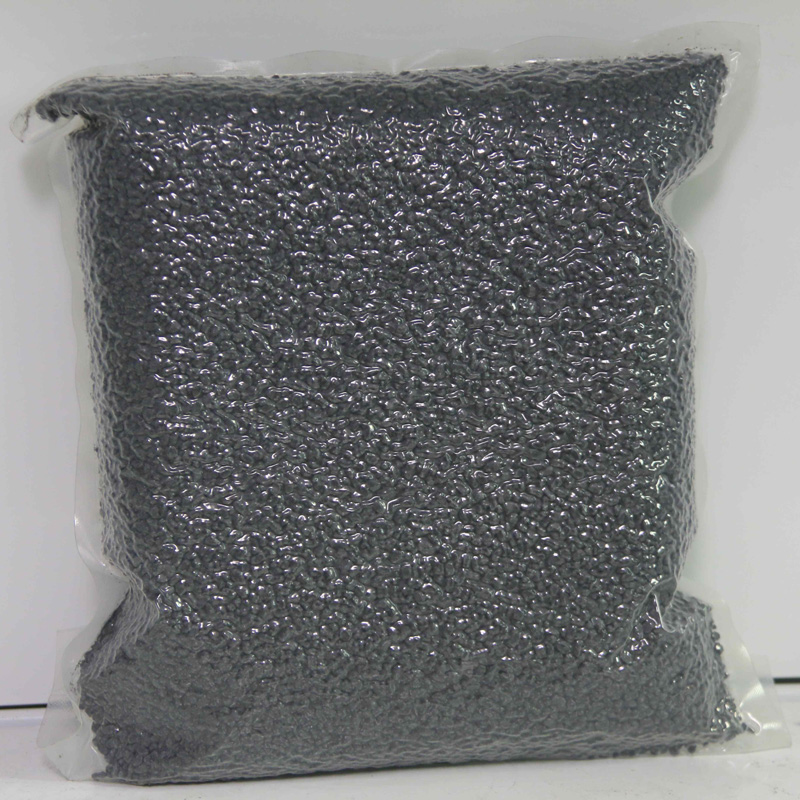

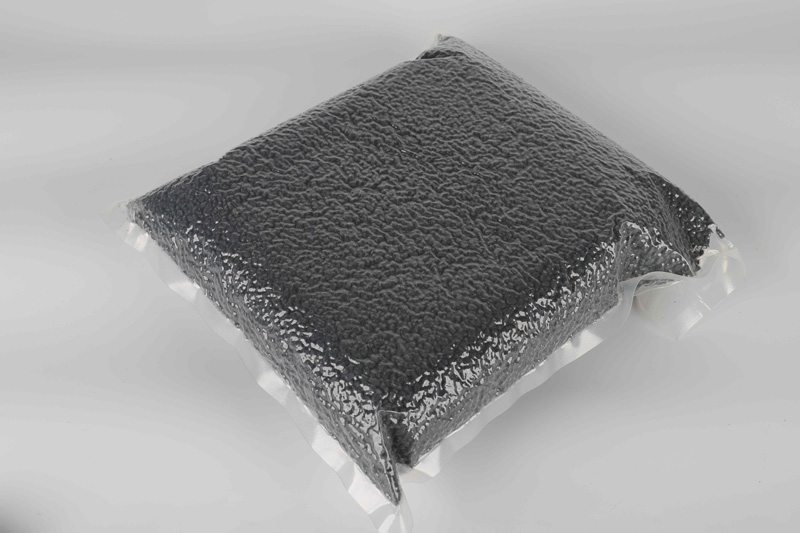

Black defoamer desiccant masterbatch is a specialized masterbatch designed to eliminate moisture-induced issues during plastic processing while also providing a black coloration. It combines desiccating agents, black pigments, and a compatible carrier resin, offering dual functionality for applications requiring both moisture control and black coloration.

Characters

Color:White/Gray/Black

Carrier:PE/PP

MFI( g/10min):0.5-50

Density(g/cm3):1.5-2.1

Volatility:1.5±0.5%

Time to keep in mixture:24 hours

Light fastness:≥5

Filler:Calcium Oxide

Water absorption:≤20

CaO content:75%-88%

Product Specifications

Product name | Black Defoamer Desiccant Masterbatch |

Items | value |

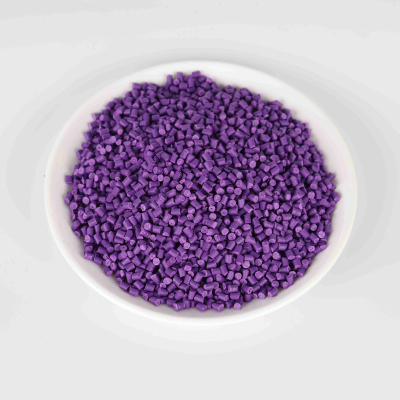

Appearance | granular |

Color | White or grey or black |

Calcium Oxide content | 70-80% |

Carrier | PE/PP |

Water absorption | 20% |

Moisture absorbent weight | 20~25±1,0% |

MFI(230°C/10min) | 5~10g/10min |

Melting Point (°C) | 120℃ |

Density(g/m?) | 1.4+/-0.1g/m? |

Volatility | 1.5+/-0.5% |

Pellet size of Masterbatch | 2.5micron |

Addition Rate(%) | 2-5% |

Packing (Net weight) | 25 Kg/ bags Vacuum packaging |

Time to keep in Mixture | 20 to 48 hours |

Product Application

Recycled Plastics: Ideal for processing recycled materials where residual moisture is a common issue.

Packaging: Used in black plastic films, bags, and containers to maintain appearance and quality.

Injection Molding: Enhances the quality of black molded components by reducing surface defects.

Extrusion: Improves dimensional stability and surface finish in black pipes, profiles, and sheets.

Automotive: Used for black components to ensure uniform coloration and high surface quality.

Usage Guidelines

Dosage: Recommended at 1–5% by weight, depending on the moisture content of the raw material.

Mixing: Ensure even blending with the base resin for optimal moisture absorption and color dispersion.

Storage: Store in a cool, dry environment to prevent premature activation of desiccants.

Processing Conditions: Adjust parameters to suit the resin and masterbatch properties for best results.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

![Black Defoamer Desiccant Masterbatch Black Defoamer Desiccant Masterbatch]()

Company Profile

Jinan Oke Plastics Co., Ltd. is a leading manufacturer dedicated to the research, development, production, and sales of plastic masterbatches, pigments, and additives. Our extensive product portfolio includes black, white, color, functional, and filling masterbatches, widely applied in injection molding, extrusion, film blowing, and coating processes for materials such as PE, PP, PC, HIPS, and ABS.

With state-of-the-art production capabilities, we operate five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, achieving an annual output of over 20,000 tons of masterbatches and 3,000 tons of pigments. Backed by a highly skilled R&D team, cutting-edge facilities, and advanced color-matching technology, we provide customized color solutions and comprehensive technical support tailored to our clients’ needs.

Committed to international quality standards, our products are exported to Europe, America, Southeast Asia, the Middle East, and South America. With a strong focus on quality, innovation, and customer satisfaction, Jinan Oke Plastics has built a solid reputation as a trusted partner in the global plastics industry.

![Black Defoamer Desiccant Masterbatch Black Defoamer Desiccant Masterbatch]()

Why choose us?

We utilize advanced production technology and continuously innovate to enhance our products.

Our products undergo rigorous testing to ensure guaranteed quality and reliability.

Equipped with modern production and testing facilities, we uphold the highest manufacturing standards.

Using premium raw materials, cutting-edge equipment, and refined processes, we ensure superior product quality.

With high productivity and efficient operations, we guarantee fast delivery.

Our R&D department is at the forefront of industry innovation.

We boast strong production capacity and rapid order fulfillment.

We offer high-quality products at competitive prices.

Our experienced marketing managers provide expert insights and support.

Our professional design team develops innovative and customized solutions.

We deliver exceptional after-sales service to ensure customer satisfaction.

Choosing us means receiving our utmost dedication and commitment.

We are committed to resolving any issues that may arise during the trading process.

We guarantee the quality of our products, ensuring they meet and exceed your expectations.