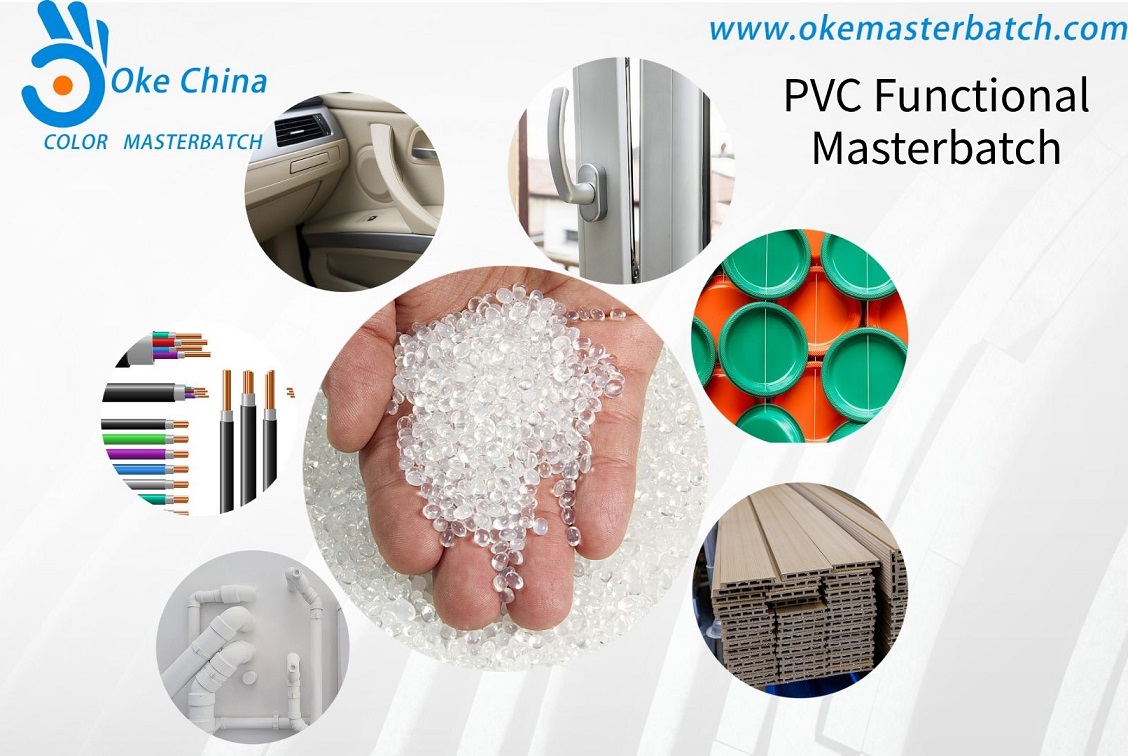

PVC Functional Masterbatch

Polyvinyl Chloride (PVC) functional masterbatch is a high-performance modified material processed through specialized techniques using PVC resin as the carrier. By incorporating various functional additives (such as plasticizers, stabilizers, lubricants, anti-aging agents, flame retardants, etc.), it enhances the physical properties, processing performance, and special functionalities of PVC products. It is widely used in construction materials, wires & cables, medical devices, automotive parts, packaging materials, and more.

1. Product Overview

Polyvinyl Chloride (PVC) functional masterbatch is a high-performance modified material processed through specialized techniques using PVC resin as the carrier. By incorporating various functional additives (such as plasticizers, stabilizers, lubricants, anti-aging agents, flame retardants, etc.), it enhances the physical properties, processing performance, and special functionalities of PVC products. It is widely used in construction materials, wires & cables, medical devices, automotive parts, packaging materials, and more.

2. Key Features

Excellent Processing Performance

Improves PVC melt flowability, enhancing extrusion and injection molding efficiency.

Reduces plate-out and scorching during processing, ensuring stable production.

Enhanced Material Properties

Increases mechanical strength, toughness, and weather resistance of PVC products.

Optimizes surface gloss and minimizes defects (e.g., fish eyes, bubbles).

Diverse Functionalities

Flame-Retardant Masterbatch: Suitable for wires, cables, and fireproof building materials, complying with UL94, GB/T, and other flame-retardant standards.

UV-Resistant Masterbatch: Improves outdoor product durability, extending service life.

Antibacterial Masterbatch: Ideal for medical devices and food packaging, inhibiting bacterial growth.

Conductive/Anti-Static Masterbatch: Used in electronic packaging, anti-static flooring, and other specialized applications.

Eco-Friendly & Safe

Complies with RoHS, REACH, and other environmental regulations; some products meet FDA food-grade standards.

Low VOC emissions, heavy-metal-free, supporting green manufacturing.

3. Major Applications

Construction Industry: PVC profiles, pipes, flooring, and wall panels with improved weather resistance and mechanical strength.

Wires & Cables: Enhances insulation and flame retardancy for power and communication cable sheathing.

Packaging Materials: Food-grade films, bottle caps, etc., combining transparency and hygiene safety.

Automotive Industry: Dashboard panels, sealing strips, and other components with enhanced heat and impact resistance.

Medical Devices: IV tubes, medical films, etc., meeting biocompatibility requirements.

4. Technical Advantages

Customized Formulations: Adjustable hardness, color, and functionality based on customer needs.

High Dispersion: Nano-scale additive distribution ensures stable product performance.

Energy Efficiency: Reduces processing energy consumption, improving production efficiency and cost-effectiveness.

5. Usage Recommendations

Recommended dosage: 1%~5% (adjustable based on performance requirements).

Storage conditions: Keep in a cool, dry place; avoid high temperature and humidity. Shelf life: 12 months.

6. Conclusion

As a key material for upgrading PVC products, PVC functional masterbatch significantly enhances product value and meets high-end market demands. We are committed to providing high-performance, eco-friendly solutions—welcome to inquire about cooperation!