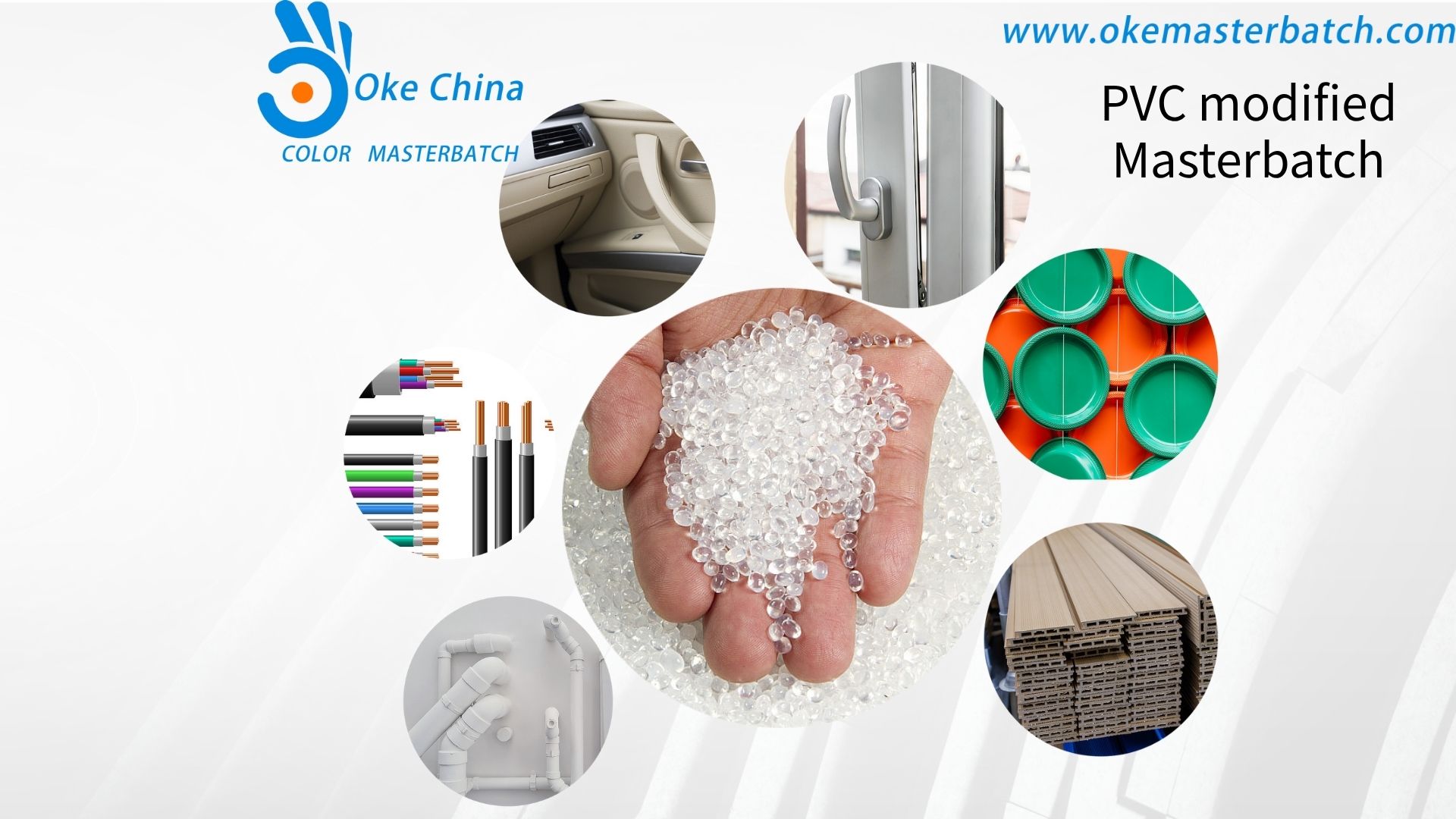

Polyvinyl chloride (PVC) modified masterbatch

Polyvinyl chloride (PVC), as a widely used thermoplastic, plays a significant role in industries such as construction, wire and cable, automotive, and medical applications. However, PVC inherently suffers from brittleness, poor thermal stability, and limited processing performance, necessitating modification technologies to optimize its properties. Our company’s PVC modified masterbatch series covers multiple functionalities, including toughening, cross-linking, filling, and thermal stabilization, significantly enhancing the comprehensive performance of PVC materials to meet stringent industry demands.

1. Toughening Masterbatch – Improved Impact Resistance for Broader Applications

Product Features:

Utilizes elastomers (e.g., CPE, ACR, MBS) or nanocomposites as toughening agents, ensuring excellent compatibility with the PVC matrix.

Significantly enhances the notched impact strength of PVC while reducing low-temperature brittleness, ideal for impact-resistant applications such as outdoor building materials, pipes, and automotive components.

Optimizes processing fluidity, reducing internal stress and preventing cracking in finished products.

Typical Applications:

Window and door profiles, PVC fittings, sports equipment, and other products requiring high toughness.

2. Cross-Linking Masterbatch – Enhanced Heat Resistance and Mechanical Properties

Product Features:

Employs peroxide or silane cross-linking technology to form a three-dimensional network structure between PVC molecular chains, improving heat resistance, creep resistance, and dimensional stability.

Cross-linked PVC exhibits significantly higher tensile strength and wear resistance, suitable for high-temperature environments or long-term load-bearing applications.

Compatible with lead-free eco-friendly additives, complying with RoHS, REACH, and other regulatory standards.

Typical Applications:

Wire and cable insulation, heat-resistant pipes, industrial sheets, etc.

3. Filling Masterbatch – Cost Reduction and Performance Optimization

Product Features:

Incorporates inorganic fillers such as calcium carbonate (CaCO₃), talc, or wollastonite, with surface modification to enhance interfacial bonding with PVC.

Effectively reduces raw material costs while improving rigidity, heat resistance, and surface finish of products.

Special formulations balance filling and toughening effects, avoiding the strength reduction commonly seen with traditional fillers.

Typical Applications:

Flooring sheets, wall panels, low-cost pipes, and other mass-produced items.

4. Thermal Stabilization Masterbatch – Extended Processing Life and Safety Assurance

Product Features:

Uses environmentally friendly thermal stabilizers such as calcium-zinc (Ca/Zn) or organotin to replace traditional lead-based additives, preventing thermal degradation during PVC processing.

Effectively suppresses HCl release during processing, improving melt stability and extending continuous production time.

Some formulations include lubrication functions, reducing mold deposits and enhancing surface quality.

Typical Applications:

Medical tubing, food packaging films, children’s toys, and other applications with strict environmental requirements.

Comprehensive Advantages

Customization Services: Adjust masterbatch formulations to balance performance and cost based on customer needs.

One-Stop Solutions: Support composite modifications (e.g., toughening-filling, cross-linking-stabilization) to simplify downstream processing.

Eco-Friendly: Complies with international environmental standards, supporting sustainable development.

Through scientific formulation design and process optimization, our PVC modified masterbatch series helps customers overcome material performance limitations and enhance market competitiveness. Contact our technical team for samples and tailored solutions!