Flame Retardant Masterbatch

Improved Safety: The primary benefit is increased fire resistance, which reduces the likelihood of fire spreading in applications like electrical cables, automotive parts, and building materials. This can be critical in industries where fire safety is a top priority.

Ease of Use: Masterbatches are pre-dispersed formulations, meaning manufacturers can easily incorporate them into the production process without needing to handle pure chemicals. This saves time and improves consistency in the final product.

·Customization: Flame retardant masterbatches can be tailored to meet specific fire resistance standards or performance criteria, depending on the application. They come in various formulations that cater to different materials (like PE, PP, PVC) and fire resistance requirements.

Compliance with Regulations: Many industries are required to meet certain fire safety standards (e.g., UL94, IEC, and ISO). Flame retardant masterbatches help manufacturers meet these stringent requirements without the need for separate fireproofing treatments.

Cost-Effective: Using masterbatches can be more economical than adding individual flame retardant chemicals, as the formulation is optimized for performance and cost, reducing waste and maximizing efficiency.

Improved Durability: The flame retardants in the masterbatch often provide additional benefits like heat resistance and better material longevity under extreme conditions, enhancing the overall lifespan of the final product.

Non-Toxic Options: Many modern flame retardant masterbatches are being developed with non-toxic additives, reducing environmental and health risks compared to older flame retardants that may release harmful substances when exposed to heat or fire.

Enhanced Aesthetic Qualities: Flame retardant masterbatches can often be added without significantly affecting the color, texture, or clarity of the material, making them suitable for consumer-facing products where appearance is important.

Flame retardant masterbatch is a concentrated mixture of additives, such as flame retardants, that are incorporated into plastics to reduce their flammability. These masterbatches are typically designed to be mixed with base polymer resins during the manufacturing process, like extrusion or injection molding. The purpose is to enhance the fire resistance of the final product.

1.Character:

Product name | Flame Retardant Masterbatch |

Carrier | PP/PE/PA/PET |

Application | PP/PET/PA6/PA66/Bobbin/carpet/corrugated pipe/Injection molded parts |

Recommend Dosage | 2~4% |

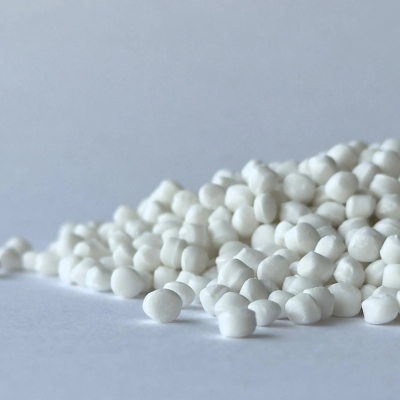

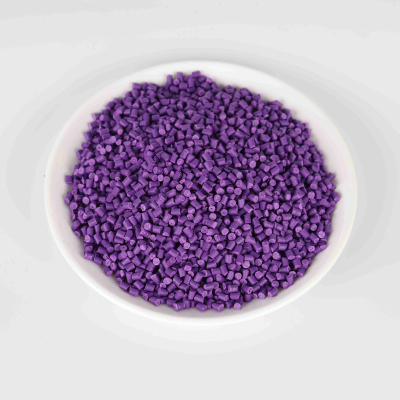

Shape | pellets/granules |

Flame Retardant Content | 50% |

Decomposition Temperature | 330℃ |

Water/Moisture | <0.2% |

2.Application :

It is widely used in Injection molding, extrusion, modification. It can be widely used in energy mining industry pipeline systems such as gas transmission pipes, mineral pipes, wire and cable such as cables, wire bushings, etc., packaging materials such as films, woven bags, etc., and outdoor facilities such as outdoor rattan chairs, stadium seats, industrial filters, safety nets, etc.

3.Why choose us?

We have advanced production technology, constant innovation.

We promise that our product has passed through rigorous test, the quality can be guaranteed and reliable.

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

We will do our best for the customer as long as you choosing us.

We promise to solve all the problems during trading process.

We promise our quality and the products will be approved by your side.

4.Packaging And Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.