Product Introduction

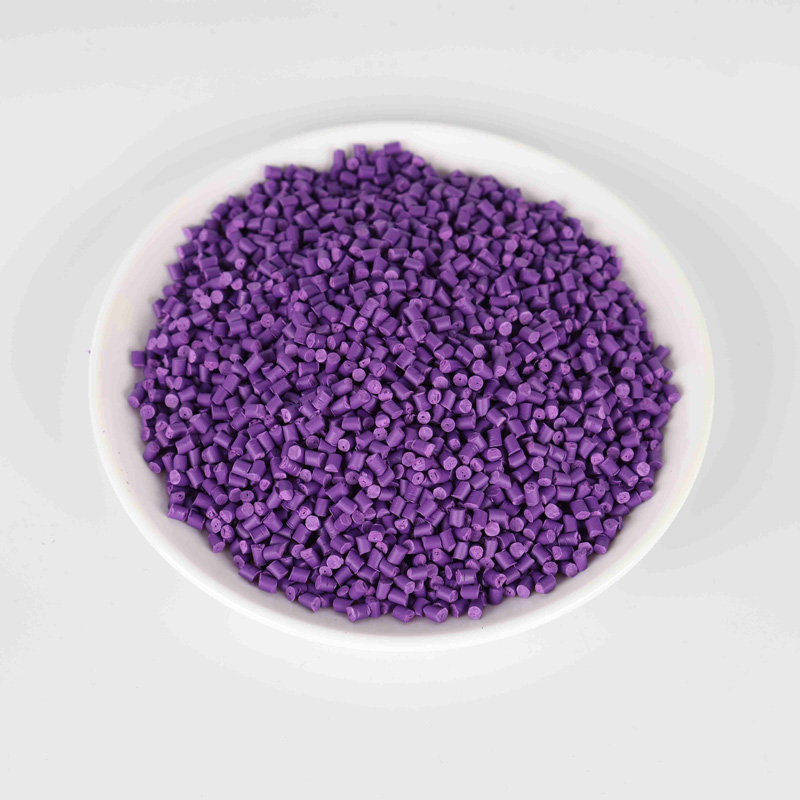

Purple color masterbatch is a concentrated mixture of purple pigments, additives, and a carrier resin, used to impart vibrant and consistent purple shades to plastic products. Known for its versatility, it offers precise and reproducible color solutions for various industries.

Characters

Suitable for plastic varieties: PP/PE

Reference ratio: 100/1-3

Light fastness: 7 (grade)

Carrier: PP / PE

Level: General

Active ingredient content: according to customer requirements

Color: various colors

Carrier: PE ;

Application: plastic products ;

Melting:105℃;

Temperature resistance: 300℃

Application: film, pipe, sheet, injection

Pigment contents: customized

Product Specifications

Product name | Purple Color masterbatch |

Appearance | 3*3mm round granule, bright and smooth surface |

Appearance | granules |

Granule diameter | 2.5*3.5mm |

Application ratio | 3-4% |

Carbon black concentration | 40% |

Carbon black content | 30% |

Carbon black content | 45% |

Carbon type | N330/N326 |

Carrier | PE |

Chromatic aberration ΔE | ≤0.5 |

Coloring Strength | 120-130% |

Content of carbon black | 40% |

Density | 1.22g/cm3 |

Product Application

Packaging: Cosmetic containers, caps, films, and specialty packaging.

Consumer Goods: Toys, household products, and decorative items.

Textiles: Fibers and non-woven fabrics for various applications.

Automotive: Decorative components and trims.

Construction: Profiles, pipes, and fittings with aesthetic appeal.

Agriculture: Nets, films, and other equipment requiring distinct coloration.

Cosiderations for Selecting Purple Masterbatch

Shade & Opacity: Define the desired hue and depth of color.

Base Resin: Ensure compatibility with the polymer used in your application.

Processing Conditions: Account for temperature and shear levels during manufacturing.

Additives: Opt for additional features like UV stabilization, anti-static properties, or flame retardancy if needed.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

![Purple Color Masterbatch Purple Color Masterbatch]()

Company Profile

Jinan Oke Plastics Co., Ltd. is a premier manufacturer specializing in the research, development, production, and sales of plastic masterbatches, pigments, and additives. Our diverse product lineup includes black, white, color, functional, and filling masterbatches, extensively applied in injection molding, extrusion, film blowing, and coating for materials like PE, PP, PC, HIPS, and ABS.

Equipped with five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, we boast an annual production capacity of over 20,000 tons of masterbatches and 3,000 tons of pigments. Supported by a highly skilled R&D team, cutting-edge production technology, and advanced color-matching systems, we deliver customized color solutions and comprehensive technical support tailored to our clients’ needs.

Adhering to international quality standards, our products are exported to Europe, America, Southeast Asia, the Middle East, and South America. Through our commitment to excellence, innovation, and customer satisfaction, we have built a strong reputation in the industry.

![Purple Color Masterbatch Purple Color Masterbatch]()

Why choose us?

We utilize cutting-edge production technology and foster continuous innovation.

We ensure that our products undergo thorough testing, guaranteeing their quality and reliability.

Our facilities are equipped with state-of-the-art production and testing equipment.

We source high-quality raw materials, use advanced facilities, and follow precise production processes.

We maintain high productivity and ensure prompt delivery.

Our R&D department is a leader in its field.

We have robust production capabilities and offer rapid delivery.

We provide top-quality products at competitive prices.

Our marketing team is highly experienced and skilled.

We have a professional design team dedicated to innovation.

We offer exceptional after-sales support and service.

We are committed to going above and beyond for our customers.

We guarantee to resolve any issues during the trading process.

We stand behind our product quality, ensuring that it meets your approval.