Product Introduction

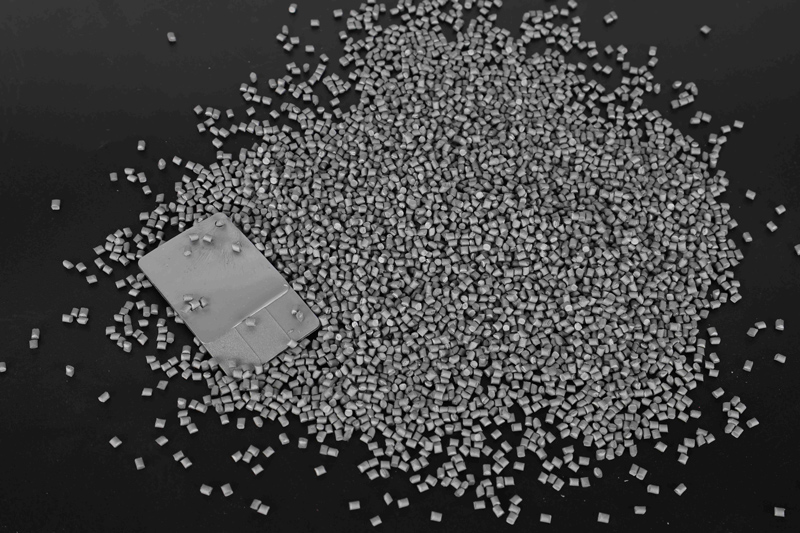

Grey color masterbatch is a concentrated blend of grey pigments, additives, and a carrier resin designed to color plastic products. It provides consistent, high-quality coloring and is widely used across various industries for its versatility and performance.

Characters

Suitable for plastic varieties: PP/PE

Reference ratio: 100/1-3

Light fastness: 7 (grade)

Carrier: PP / PE

Level: General

Active ingredient content: according to customer requirements

Color: various colors

Carrier: PE ;

Application: plastic products ;

Melting:105℃;

Temperature resistance: 300℃

Application: film, pipe, sheet, injection

Pigment contents: customized

Product Specifications

Product name | Grey Color masterbatch |

Appearance | 3*3mm round granule, bright and smooth surface |

Appearance | granules |

Granule diameter | 2.5*3.5mm |

Application ratio | 3-4% |

Carbon black concentration | 40% |

Carbon black content | 30% |

Carbon black content | 45% |

Carbon type | N330/N326 |

Carrier | PE |

Chromatic aberration ΔE | ≤0.5 |

Coloring Strength | 120-130% |

Content of carbon black | 40% |

Density | 1.22g/cm3 |

Product Application

Construction: Pipes, profiles, electrical conduits, and fittings.

Packaging: Containers, caps, films, and trays.

Automotive: Interior and exterior parts, dashboards, and trims.

Consumer Goods: Electrical appliances, furniture, and toys.

Textiles: Fibers and yarns for fabric manufacturing.

How to choose grey masterbatch?

Shade and Opacity: Specify the required tone and coverage.

Resin Type: Ensure compatibility with the base polymer.

Processing Conditions: Consider temperature and shear stress during production.

Additives: Opt for additional features like UV resistance or improved mechanical properties if required.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

![Grey Color Masterbatch Grey Color Masterbatch]()

Company Profile

Jinan Oke Plastics Co., Ltd. is a leading manufacturer specializing in the research, development, production, and sales of plastic masterbatches, pigments, and additives. Our extensive product portfolio includes black, white, color, functional, and filling masterbatches, widely used in injection molding, extrusion, film blowing, and coating for materials such as PE, PP, PC, HIPS, and ABS.

Equipped with five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, we achieve an annual output of over 20,000 tons of masterbatches and 3,000 tons of pigments. With a highly skilled R&D team, state-of-the-art production facilities, and advanced color-matching systems, we provide customized color solutions and comprehensive technical support to meet diverse customer needs.

Committed to international quality standards, our products are exported to Europe, America, Southeast Asia, the Middle East, and South America. We have built a strong reputation for quality, innovation, and customer satisfaction, consistently delivering excellence in every product we produce.

![Grey Color Masterbatch Grey Color Masterbatch]()

Why choose us?

We utilize advanced production technology and continuously innovate.

We ensure that our products undergo rigorous testing, guaranteeing reliable and high-quality performance.

Our facilities are equipped with modern production and testing equipment.

We use premium raw materials, state-of-the-art machinery, and refined manufacturing processes.

Our high productivity enables fast and efficient delivery.

Our R&D department is at the forefront of industry advancements.

We possess strong manufacturing capabilities and ensure rapid delivery.

We offer high-quality products at competitive prices.

Our team includes experienced marketing professionals.

We have a dedicated and skilled design department.

We provide outstanding after-sales support.

Choosing us means receiving our full commitment to your satisfaction.

We guarantee to resolve any issues that may arise during the trading process.

We stand by our quality, ensuring our products meet your expectations.