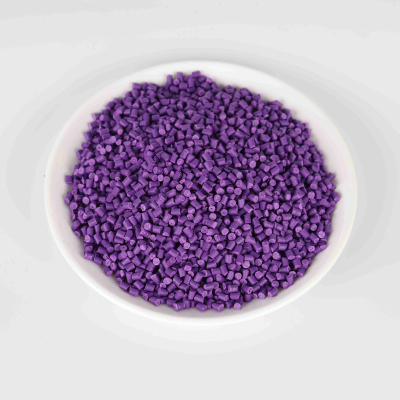

Injection Molding Masterbatch

High Dispersion: The carbon black pigment in masterbatch is evenly dispersed throughout the resin to ensure consistent coloring.

Improved Processing: Masterbatch can make the injection molding process easier, as it is already pre-mixed and reduces the need for additional pigment handling or mixing during production.

Enhanced Properties: Carbon black, often used in black masterbatch, can also improve UV resistance, electrical conductivity, and weathering properties of the molded plastic, depending on the specific formulation.

Versatility: Black masterbatch can be used in a wide range of thermoplastic materials such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and more.

Product Introduction

Injection Molding Black Masterbatch

Injection molding black masterbatch is a concentrated mixture of black pigment (typically carbon black) and a carrier resin, used in the plastic injection molding process to impart color or provide other properties to the molded plastic product.

Characters

Use:High quality Carbon Black Masterbatch for PP injection products

Appearance:Black

Carbon Black:45%

Forms:Granules

Dosage:2-6%

Processing Method:Pipe Extrusion,Injection Molding

Moisture Content:<1500ppm

Bulk Density:1191kg/m3

Standard:Enviormental

Certificate:ROHS Approved

Product Specifications

Product name | Injection Molding Black masterbatch |

Carrier | PE / PP / EVA |

Content of Carbon Black | 10%- 50% |

Light and weather resistant | 4-8 level |

Color difference | ≤0.8% |

MFI 21.6KG/190℃ | 1-50g /10min |

Phase Fusibility | PE/PP/ EVA |

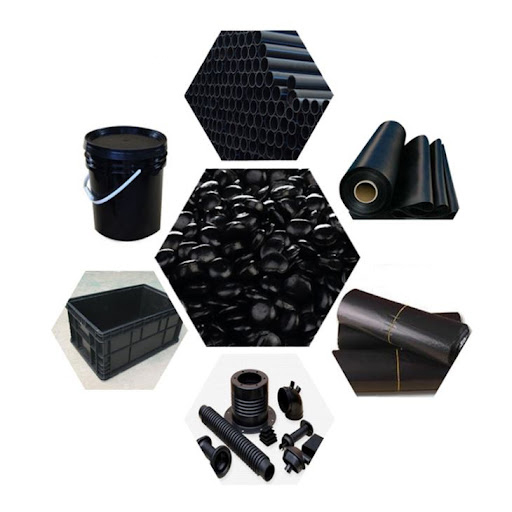

Product Application

Injection molding black masterbatch is used in a wide variety of applications across several industries, offering color consistency, enhanced mechanical properties, and better processing control. Here are some of the common applications:

Interior Parts: Dashboard components, trims, knobs, and interior panels often use black masterbatch for color consistency and UV resistance.

Exterior Parts: Parts exposed to the elements, like bumpers, grilles, and moldings, benefit from the UV stability and weathering resistance that carbon black provides.

Electrical Components: Black masterbatch can improve conductivity and help reduce static buildup in certain electrical applications.

2). Packaging

Food and Beverage Packaging: Plastic containers and bottles, particularly those made from polyethylene or polypropylene, are commonly produced with black masterbatch to achieve a desired color and enhanced UV protection.

Flexible Packaging: Black masterbatch is used in films, bags, and pouches for better aesthetics, strength, and barrier properties.

Cosmetic Packaging: Black is often used in packaging for cosmetic products like bottles, jars, and caps for a sleek, premium look.

3). Consumer Electronics

Casing and Housings: Injection molded plastic components, such as TV frames, computer casings, or mobile phone housings, often use black masterbatch for a uniform color and durability.

Cable Insulation: Electrical cables and wires, particularly those requiring UV resistance or conductive properties, benefit from black masterbatch in their insulation.

4). Building & Construction

Piping: Black masterbatch is frequently used in the production of PVC pipes, both for functional and aesthetic reasons. The carbon black helps with UV stability, protecting the pipes from degradation when exposed to sunlight.

Roofing Materials: Roofing membranes, coatings, and sheets often incorporate black masterbatch for better UV resistance and aesthetic appeal.

Insulation Materials: Some insulation products, particularly those used for cables and wires, are produced using black masterbatch.

5). Agricultural Applications

Agricultural Films: Black masterbatch is commonly used in mulching films, greenhouse films, and other agricultural applications to help with light absorption or to block sunlight, controlling plant growth and temperature regulation.

Greenhouse and Shade Nets: Black plastic nets and shade materials are used for controlling environmental conditions in greenhouses.

6). Consumer Goods

Toys: Plastic toys or items with specific color requirements (like black) often use black masterbatch for uniformity.

Appliances: Household appliances, such as vacuum cleaners, coffee makers, or washing machine panels, frequently use black masterbatch for their aesthetic finish.

7). Sports Equipment

Golf Balls: Some golf balls are produced with black masterbatch to improve durability and performance.

Outdoor Equipment: Products like protective gear, outdoor furniture, and sports accessories may also use black masterbatch for color and UV protection.

8). Industrial Applications

Cable Insulation: Black masterbatch is often used for insulating and jacketing electrical cables due to its UV and weather resistance properties.

Electrical Housings: Electrical enclosures and protective covers for machinery can be made using black masterbatch for both functional and aesthetic reasons.

9). Consumer Packaging and Goods

Bottles and Jars: Many types of packaging, especially for products that require opaque containers (e.g., for light-sensitive products like certain chemicals or cosmetics), utilize black masterbatch.

Cosmetic Containers: Many high-end cosmetic products (such as jars, bottles, and caps) use black masterbatch for a sleek, premium look.

10). Medical and Pharmaceutical

Medical Devices: Some medical components or equipment housings, like blood bags or IV drip bags, can use black masterbatch for added stability and UV protection, particularly for light-sensitive substances.

Pharmaceutical Packaging: Black is sometimes used in medical packaging to block UV light and preserve the contents of the packaging.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

Company Profile

Jinan Oke Plastics Co., Ltd. is a specialized manufacturer engaged in the research, development, production, and sales of plastic masterbatches, pigments, and additives. Our product portfolio includes black, white, color, functional, and filling masterbatches, catering to a wide range of applications such as injection molding, extrusion, film blowing, and coating for materials like PE, PP, PC, HIPS, and ABS.

Equipped with five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, we achieve an annual production capacity of over 20,000 tons of masterbatch and 3,000 tons of pigments. Our skilled R&D team, state-of-the-art manufacturing facilities, and advanced color matching systems enable us to deliver tailor-made color solutions and comprehensive technical support.

Committed to quality, innovation, and customer satisfaction, our products comply with international standards and are exported to Europe, America, Southeast Asia, the Middle East, and South America, earning global recognition for reliability and performance.

FAQ

Q1:Do we provide free sample of the products

A: Of course,please feel free to tell me your specific require,and then we will make the corresponding customized sample to you .

Q2: What is the shipping terms?

A:FOB Qingdao,others accepted

Q3: How about your payment?

A:T/T,L/C,western union.

Q4:What kind of plastic do our masterbatch fit?

A:Perfectlysuit:PE/PP/PC/ABS/PET/HIPS/GPPS/PA/PMMA/AS/POM/PU/TPE.

Q5: What’s your advantage products?

A:Transparent filler masterbatch(NaSO4/BaSO4/Talc filler masterbatch)