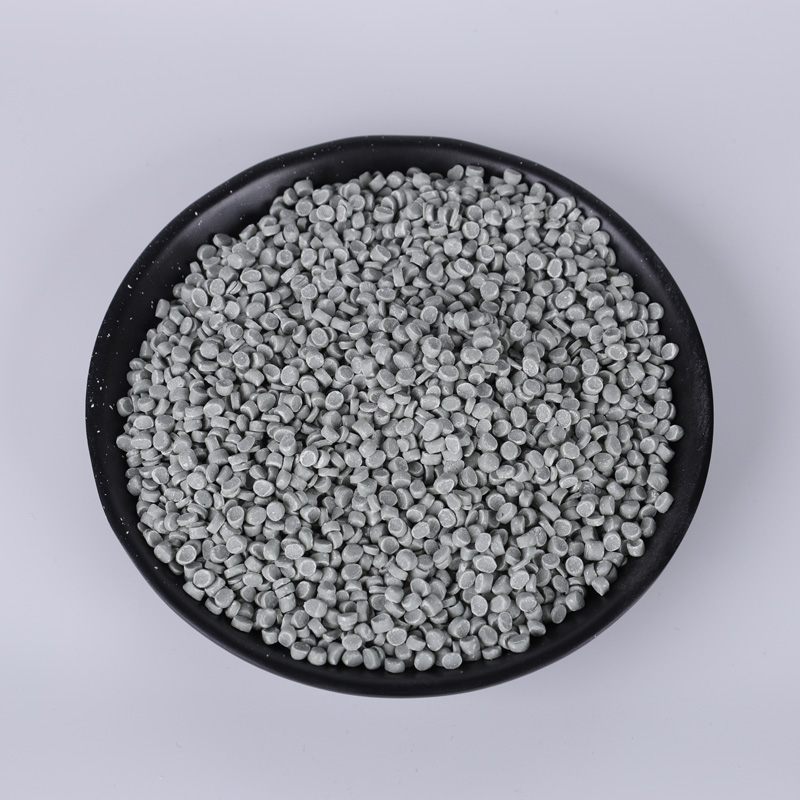

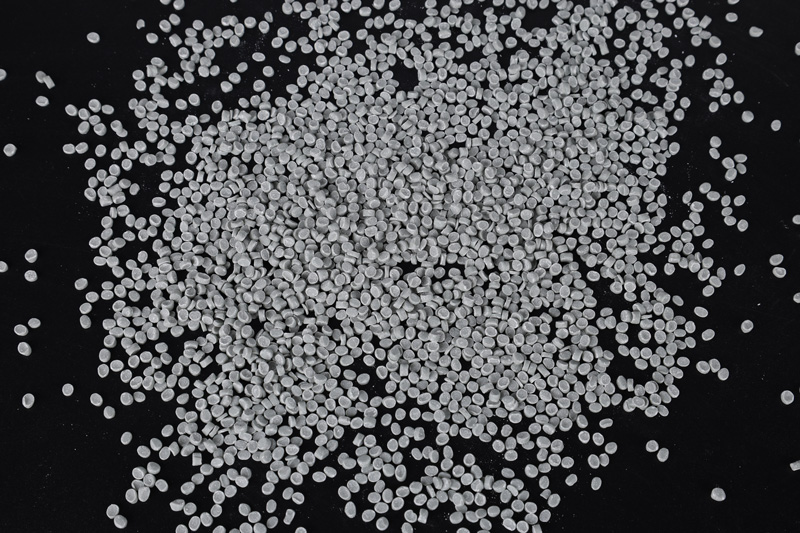

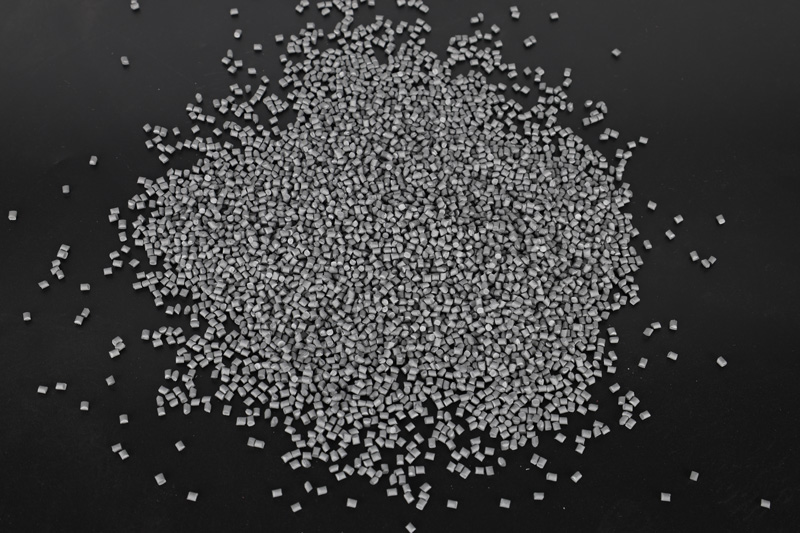

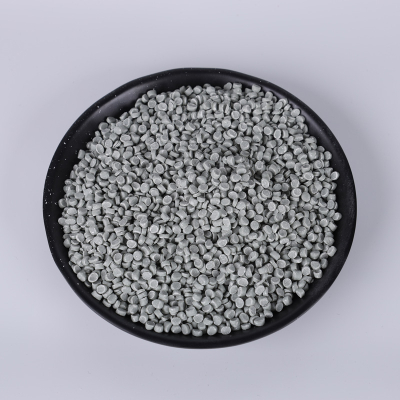

Product Introduction

Talc additive masterbatch is a type of plastic compound where talc (a mineral primarily composed of magnesium, silicon, and oxygen) is added to a base polymer in the form of a masterbatch. The masterbatch is a concentrated mixture of the additive (in this case, talc) and the polymer, which is then diluted with more polymer during the manufacturing process to achieve the desired properties.

Product Specifications

Product name | Talc Masterbatch |

Index | Value |

Carrier | PP |

Calcium Carbonate Content | 75%-85% |

MFI (5KG/190°C) | 5-40g/10min |

Density | 1.8-2.2g/cm³ |

Intermiscibility | PE/PP/PVC |

Product Application

Talc Additive Masterbatch is widely used in a range of industries, including automotive, packaging, construction, and consumer goods. It can be added to various types of polymers such as polypropylene, polyethylene, and PVC.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

![Talc Additive Masterbatch Talc Additive Masterbatch]()

Company Profile

Jinan Oke Plastics Co., Ltd. is a premier manufacturer specializing in the research, development, production, and distribution of plastic masterbatches, pigments, and additives. Our extensive product portfolio includes black, white, color, functional, and filling masterbatches, widely utilized in injection molding, extrusion, film blowing, and coating applications for materials such as PE, PP, PC, HIPS, and ABS.

Equipped with cutting-edge production technology, we operate five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, enabling an annual production capacity of over 20,000 tons of masterbatches and 3,000 tons of pigments. Backed by a highly skilled R&D team, state-of-the-art facilities, and advanced color-matching technology, we offer tailored color solutions and comprehensive technical support to meet the specific needs of our clients.

Committed to international quality standards, our products are recognized and exported to markets across Europe, America, Southeast Asia, the Middle East, and South America. With a steadfast focus on quality, innovation, and customer satisfaction, Jinan Oke Plastics has established itself as a trusted and forward-thinking leader in the global plastics industry.

![Talc Additive Masterbatch Talc Additive Masterbatch]()

Why choose us?

We utilize advanced production technology and continuously innovate to enhance our processes.

Our products undergo rigorous testing to ensure guaranteed quality and reliability.

Equipped with modern production and testing facilities, we use high-quality raw materials, state-of-the-art equipment, and refined manufacturing procedures.

With high productivity and efficient operations, we ensure fast delivery and seamless order fulfillment.

Our industry-leading R&D department drives innovation, while our strong production capacity supports rapid turnaround times.

We offer premium-quality products at competitive prices, backed by an experienced marketing team and a professional design department.

Our commitment extends beyond production—we provide exceptional after-sales service, ensuring customer satisfaction at every stage.

By choosing us, you gain a dedicated partner committed to resolving any challenges throughout the trading process.

We stand by our quality and guarantee that our products will meet and exceed your expectations.