Polylactic acid: a solution to plastic pollution.

Plastic, a material that has revolutionized modern life, brings convenience while also placing a heavy burden on the environment. Disposable plastics, such as

packaging bags, lunch boxes, and beverage bottles, often take hundreds of years to degrade in the natural environment, contributing to the growing problem

of white pollution. To address this challenge, scientists have developed a green alternative: polylactic acid (PLA). Like polyhydroxyalkanoates (PHA), it is a

biodegradable, green plastic.

Humanity has a long history of using lactic acid, a key flavoring agent in yogurt, kimchi, and some fermented soy products. Lactic acid molecules contain a hydroxyl

group and a carboxyl group. Through chemical processes, lactic acid molecules can undergo dehydration and polymerization to form a series of chain-like polymers,

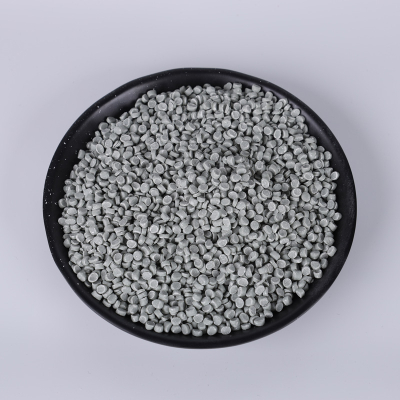

known as polylactic acid. The interactions between these polymers give polylactic acid the typical properties of plastics. With simple processing, it can be made into

transparent or translucent plastic particles, films, and fibers.

PLA is known as a "green plastic" for two main reasons. On the one hand, the raw material for PLA synthesis, lactic acid, is primarily obtained through microbial

fermentation of renewable resources (such as corn starch), eliminating reliance on petrochemicals, which are increasingly resource-dense and potentially environmentally

problematic. Microorganisms can produce lactic acid from a variety of carbon sources, including high-quality milk, starch, and yeast extract, as well as cellulose

hydrolysis products and organic acids from industrial and agricultural waste. This allows them to transform both food and waste into valuable resources. Furthermore,

the degradation process of waste PLA plastic is highly environmentally friendly. Due to its ester bonds, PLA readily undergoes hydrolysis when buried in soil, producing

lactic acid monomers or oligomers. Lactic acid, a natural carbon source for many microorganisms, is rapidly converted into carbon dioxide and water, a process that

takes only three to six months. In comparison, the natural degradation time of ordinary petrochemical plastics can be hundreds of times longer.

In the context of the "dual carbon" strategy, PLA production exemplifies a typical model of green manufacturing: using non-fossil fuels as raw materials, microbial

conversion to lactic acid, and then processing into industrial plastics through engineering technology. The final product is naturally biodegradable. By modifying

strains, optimizing culture conditions, and controlling fermentation parameters, Chinese researchers are working to enable lactic acid production to utilize more

affordable carbon sources as fermentation feedstock, significantly increasing its yield and purity. This, while reducing production costs, provides a high-quality

precursor for industrial polymerization. By 2024, my country's polylactic acid production exceeded 300,000 tons, demonstrating the country's technological

accumulation and innovative capabilities in green manufacturing. Leveraging its scientific research and industrial strength, China is advancing this green recycling

system from the laboratory to the factory floor and ultimately to the market, contributing its own solutions to global plastic pollution control and energy conservation

and emission reduction efforts.