Polylactic acid (PLA) masterbatch

1. With polylactic acid as the carrier, the colorant is made by uniformly dispersing a high proportion of pigments or dyes, which is specially used for dyeing and functional modification of PLA materials.

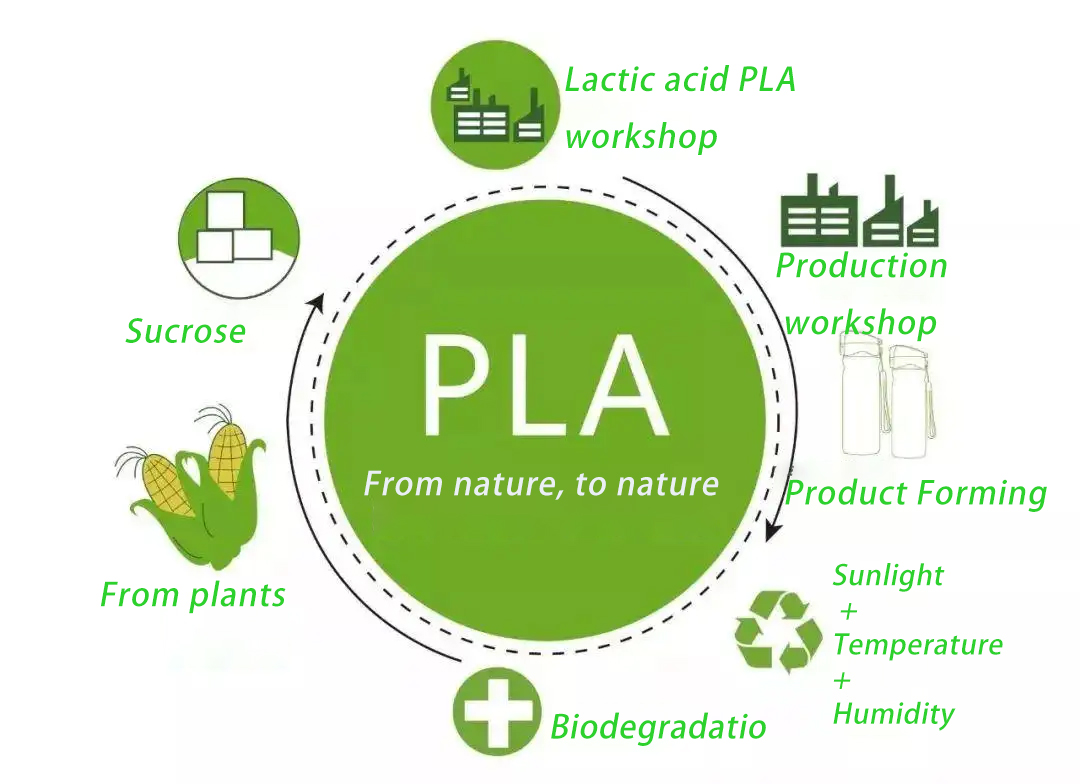

2. The production process of polylactic acid is pollution-free, and the product is a renewable and biodegradable thermoplastic.

3. It has good biocompatibility, gloss, transparency, feel and heat resistance, as well as certain bacteria resistance, flame retardancy and UV resistance.

4. Color stability, high temperature resistance (>200°C), anti-migration and anti-precipitation.

5. Processability, fluidity matches PLA, suitable for injection molding, extrusion, film blowing and other processes.

6. Circular economy: Promote the compatibility technology of masterbatch and PLA recycling system.

Product Description

Polylactic acid (PLA), also known as polylactide, belongs to the polyester family. It is a polymer made by polymerization of lactic acid, and the raw materials mainly come from renewable resources such as corn and cassava. The production process of polylactic acid is pollution-free, and the product is a renewable, biodegradable thermoplastic plastic, so it can be recycled in nature and is an ideal green polymer material.

Polylactic acid products are not only biodegradable, but also have good biocompatibility, gloss, transparency, feel and heat resistance, as well as certain bacteria resistance, flame retardancy and UV resistance. Therefore, polylactic acid is widely used in the packaging industry, agriculture, medical and health care, fiber, textile, 3D printing, automotive industry, electronic products, biodegradable plastic products and non-woven fabrics.

Product Parameters

1. Environmental protection, in line with biodegradation standards, suitable for disposable packaging, tableware and other scenarios.

2. Compatibility, no phase separation when melt blended with PLA substrate, avoiding surface defects of products.

3. Color stability, high temperature resistance (>200°C), anti-migration and anti-precipitation.

4. Processability, fluidity matches PLA, suitable for injection molding, extrusion, blown film and other processes.

Product Application

Polylactic acid (PLA) is a renewable, biodegradable thermoplastic with a wide range of applications, covering the following main areas:

1. Packaging industry: PLA is widely used in food packaging, biodegradable plastic bags, food containers, etc. due to its good transparency and processing properties.

2. Agriculture: As a bio-based material, polylactic acid can be used to produce agricultural mulch films, which can be naturally decomposed in the soil after use, reducing the problem of plastic residue.

3. Healthcare: PLA is used in the medical field to produce surgical sutures, tissue engineering scaffolds, drug sustained-release systems, etc. because of its good biocompatibility and degradability.

4. Textile industry: Polylactic acid fibers (such as PLLA) can be used to produce clothing, underwear and other textiles. These fibers usually have antibacterial and deodorizing properties.

5. 3D printing: PLA is one of the most commonly used 3D printing materials because it is easy to process, relatively low cost, and the printed products have good mechanical properties and surface finish.

6. Automotive industry: PLA can be used to produce automotive interior parts, non-load-bearing parts, etc., helping to reduce vehicle weight and improve fuel efficiency.

7. Electronic products: Polylactic acid can be used to manufacture housings and components of electronic products because it has good heat resistance and electrical insulation.

8. Biodegradable plastic products: PLA is also used to make various disposable items such as tableware, cups, straws, etc., aiming to reduce the impact of plastic waste on the environment.

9. Building materials: Polylactic acid can be used to make bioplastic wood, a degradable building material used for indoor and outdoor decoration and furniture.

These application areas of polylactic acid reflect its potential as a sustainable material, especially in reducing environmental pollution and achieving a circular economy. With the development of technology and further reduction of costs, the application scope of polylactic acid is expected to expand further.

In addition, compared with raw materials such as polyethylene (PE), polyvinyl chloride (PVC), and polypropylene (PP), polylactic acid also has excellent biodegradability, antibacterial and anti-mildew properties, which has obvious advantages.

In the textile field, polylactic acid fiber is widely used in a series of clothing textiles such as sportswear, school uniforms, underwear, home furnishings, baby clothing, gloves socks, and thermal clothing due to its friendly properties to human skin and the functions brought by special special-shaped cross-section fibers.

Packaging & Shipping

1. 25kg per bag;

2.Vacuum packaging,Plastic bag Packaging and Carton Packaging are availabled;

3. Handle carefully to avoid package damaged.

4. Store in ventilated, dry, and cool place to keep out of sun exposure and rain.

Our Advantages

1, Products meet all kinds of environmental protection requirements, with guaranteed quality

The product can meet the requirements of ISO ,SGS and other environmental protection, fire protection and video level requirements

2, Rich experience in color matching in plastic industry, which can provide customers with personalized color matching

According to the plastic parts, Pantone number and photos provided by customers, personalized color matching can be carried out, and samples after color matching can be provided for customers' confirmation

3, Professional R & D team, specialized in technology industry

All technical personnel are from the specialty of plastic pigment and plastic engineering polymer materials, and have many years of industry experience, can give R & D and production according to different requirements

4, Advanced testing and production equipment, standardized and large-scale production

It has electronic measuring instrument, computer color measuring instrument, energy dispersive X-ray fluorescence spectrometer and other testing instruments, as well as a number of international professional equipment such as single screw extruder, twin-screw extruder, injection molding machine, etc

5, Professional pre-sales and after-sales team to provide customers with thoughtful service

Telephone, email, online consultation, website message and other communication channels to provide customers with 24-hour service .

FAQ

Q:How about our package?

A:1.All the packing can be customized.

2. Generally package is 5kg/vacuum bag for defoaming masterbatch,25kg/bag for other masterbatch

Q:What are our business principles?

A:1.For the trial order, 500kgs will be acceptable.

2.We will do our best for the customer as long as you choosing us.

Q: Free sample is available?

A: Yes, please Provide your required specific, we will make customized sample to you.

Q:What kind of plastic does your masterbatch fit?

A: ABS/PP/PE/PS/PC/HDPE/LDPE

Q:What is the shipping terms?

A: FOB, EXW, CFR, CIF.

Q: What is the payment terms?

A: T/ T, L/ C Or according to customer 's requirement.

Q:Do you have any MOQ limit for masterbatch order?

A: Low MOQ,1 kilogram for sample checking is available