Defoaming/Desiccant Masterbatch

1. Definition & Function

Defoaming/Desiccant masterbatch is a functional plastic additive used to eliminate bubbles or foam generated during plastic processing, improving product surface smoothness, mechanical properties, and processing stability.

2. Defoaming Mechanism

● Reduces Surface Tension: Defoaming agents migrate to bubble surfaces, destabilizing the film and causing bubble rupture.

● Suppresses Bubble Formation: Minimizes gas entrapment in the melt, preventing microvoids.

3. Key Components

● Carrier Resin (e.g., PE, PP): Ensures compatibility with the base material.

● Defoaming Agent (e.g., silicone, mineral oil, polyether): Core functional ingredient.

● Dispersant: Promotes uniform distribution of the defoaming agent.

4. Applications

● Injection/Extrusion Molding: Eliminates flow marks, silver streaks, and other defects.

● Foamed Materials: Controls cell structure, preventing over-expansion.

● Recycled Plastics: Removes residual bubbles from reprocessed materials.

5. Selection Guidelines

● Compatibility: Must match the base polymer (e.g., PP defoaming masterbatch is unsuitable for PVC).

● Processing Temperature: High-temperature applications require heat-resistant defoamers (e.g., silicone-based).

● Dosage: Typically 0.1%–1%; excessive amounts may degrade product performance.

6. Difference from Devolatilizing Agents

● Defoaming Masterbatch: Targets bubbles in the melt during processing.

● Devolatilizing Agents: Removes moisture or volatiles from plastic pellets (pre-processing).

7. Common Market Issues

● Migration Risk: Low-quality defoamers may bleed to the surface, affecting printing/adhesion.

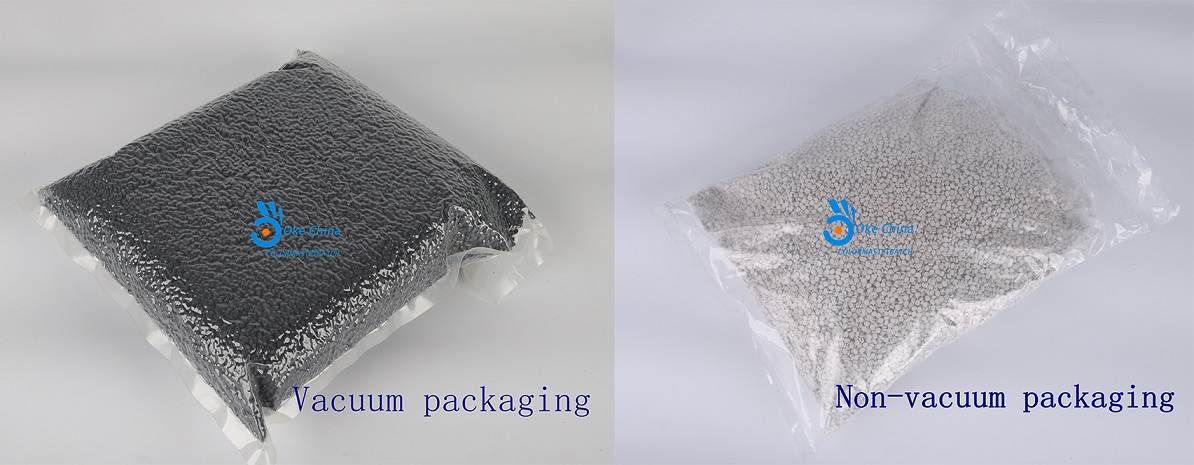

● Performance Degradation: Active components may lose efficacy over time; recommend immediate use after production.

● For optimal formulations or process-specific adaptations, lab testing is advised to verify defoaming efficiency and final product quality.