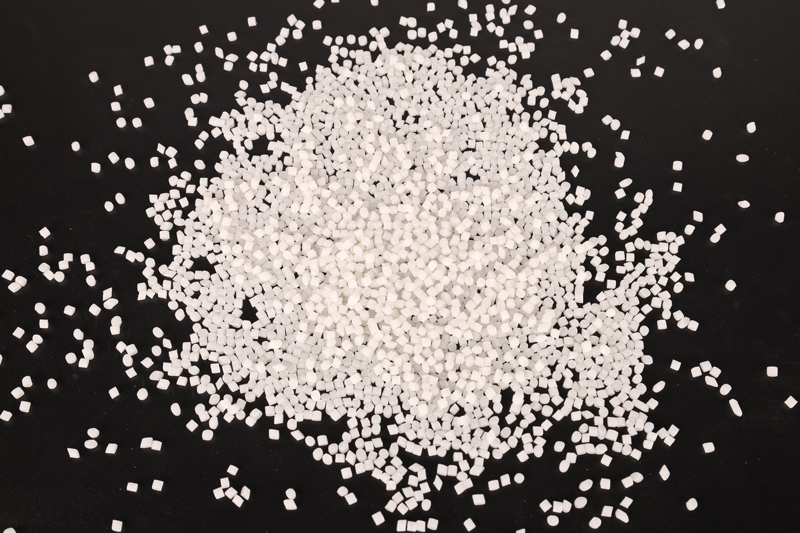

ABS White Plastic Masterbatch

High Opacity and Brightness: The masterbatch uses high-quality white pigments, often Titanium Dioxide (TiO₂), to achieve superior opacity and brightness.

Good Dispersion: Ensures the even distribution of pigments throughout the ABS resin, providing a uniform white color without streaks or patches in the final product.

Thermal Stability: ABS white masterbatch is formulated to withstand the processing temperatures typically used for ABS, which range between 210-250°C, without degradation of the pigment or additives.

Impact Resistance: The masterbatch does not compromise the mechanical properties of ABS, such as impact resistance, strength, and stiffness.

UV Stability (Optional): Some ABS white masterbatches come with added UV stabilizers to protect the product from fading or degradation due to exposure to sunlight.

Product Introduction

ABS (Acrylonitrile Butadiene Styrene) white plastic masterbatch is a concentrated mixture of white pigments, typically Titanium Dioxide (TiO₂), and other additives designed to be blended with ABS resin. This masterbatch is used to achieve a uniform white color and opacity in ABS-based products, which are known for their strength, rigidity, and impact resistance. ABS white masterbatch is used in applications that require good mechanical properties along with a bright, consistent white finish.

Characters

Materials:>Pigment, Carrier

Titanium Dioxide Content:70%

Moisture Content:0.15%

Color:white

Carrier:PE / PP

MFI(g/10min):< 48 Micrometre

Application:Film blowing, Injection molding, Blister etc.

Granual size:2.5mm

Density:0.96g/ Cubic Centimeter

Product Specifications

Product name | ABS white plastic masterbatch |

Content | 10%-50% |

Carrier | PE/PP/EVA/PVC |

Application | PE/PP/ABS/PVC |

MFI(g/10min) | 0.1-80 (Can be customized) |

Melting Point(℃) | 130-170 |

Density(g/m3) | 1.2-1.8 |

Moisture Content(%) | ≤0.15 |

Grain Diameter(mm) | 1.8-3.8 |

Package | 25kgs plastic compound bag, 5kg vacuum package |

Add Ratio | Recommend to add 2%-5% |

Product Application

Consumer Electronics: ABS is commonly used in the production of housings for electronics like computer peripherals, telephones, and household appliances, where a clean, white appearance is desired.

Automotive Components: ABS white masterbatch is used in automotive interior parts such as dashboards, trims, and door panels, where aesthetics and durability are essential.

Home Appliances: ABS is often used for products like kitchenware, vacuum cleaners, and other appliances, and the white masterbatch ensures a smooth, clean finish.

Toys: ABS is a popular material for the toy industry due to its strength and rigidity, and the masterbatch ensures a uniform white color in toys and other consumer products.

Medical Devices: ABS is used in medical applications where both strength and appearance matter, such as medical device casings and components.

Furniture: White ABS can be used in the production of components for furniture, including office chairs, tables, and fixtures.

Packaging&Storage:

1). Custom packaging is available.

2). Paper-plastic compound bag.

3). Inner layer: plastic bags; Outer layer: durable, moisture-resistant bags.

4). Each bag weighs 25kg net.

Packed in 25kg paper-plastic compound bags.

Store in a dry, cool area, avoiding direct sunlight.

Company Profile

Jinan Oke Plastics Co., Ltd. is a leading provider of plastic masterbatches, pigments, and additives, specializing in R&D, production, and sales. Our product portfolio includes black, white, color, functional, and filling masterbatches, extensively used in injection molding, extrusion, film blowing, and coating applications for materials such as PE, PP, PC, HIPS, and ABS.

Equipped with five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, we achieve an annual output of over 20,000 tons of masterbatches and 3,000 tons of pigments. Supported by a skilled R&D team, state-of-the-art manufacturing facilities, and advanced color-matching systems, we deliver customized color solutions and comprehensive technical support.

Our products comply with international standards and are exported to Europe, America, Southeast Asia, the Middle East, and South America, earning a strong reputation for quality, innovation, and customer satisfaction.

FAQ

Q1: Do you provide free samples?

A: Yes! Just tell us your needs, and we’ll prepare a custom sample.

Q2: What are your shipping terms?

A: FOB Qingdao is our standard, but other terms are available.

Q3: What payment methods do you accept?

A: We support T/T, L/C, and Western Union.

Q4: Which plastics are compatible with your masterbatch?

A: Our masterbatch is ideal for PE, PP, PC, ABS, PET, HIPS, GPPS, PA, PMMA, AS, POM, PU, and TPE.

Q5: What are your top products?

A: We specialize in transparent filler masterbatch (NaSO₄/BaSO₄/Talc filler masterbatch).