Product Introduction

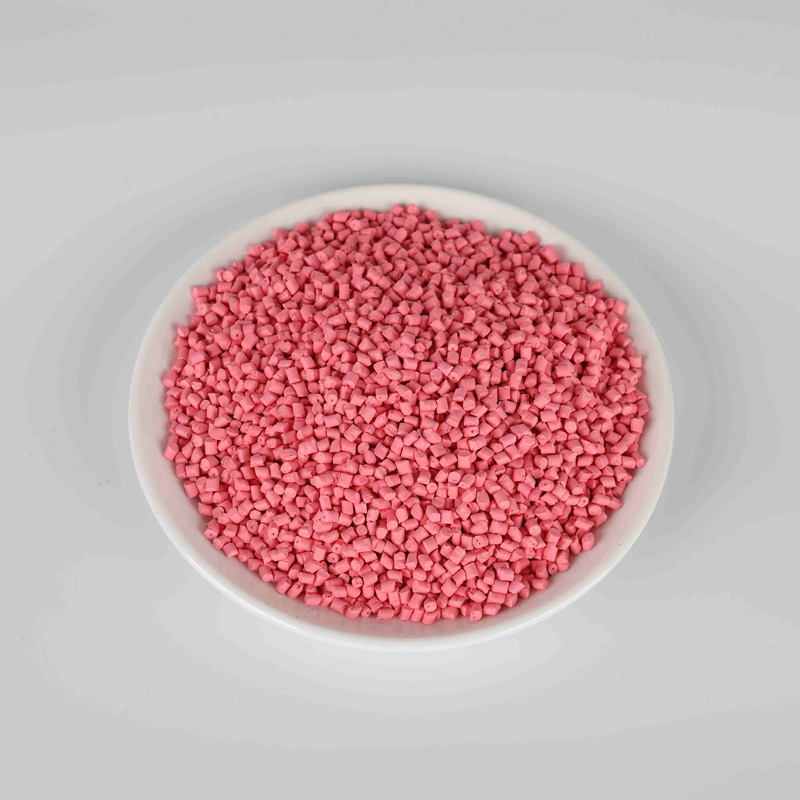

Red Color Masterbatch is a concentrated mixture of red pigments (often Titanium Dioxide for opacity, and organic or inorganic pigments for color) combined with a carrier resin, designed to impart red color to plastics. It is used across a wide range of industries to achieve consistent and vibrant red shades in plastic products. The key benefits of using red color masterbatch include cost-effectiveness, ease of processing, and the ability to produce uniform color in large production runs.

Characters

Suitable for plastic varieties: PP/PE

Reference ratio: 100/1-3

Light fastness: 7 (grade)

Carrier: PP / PE

Level: General

Active ingredient content: according to customer requirements

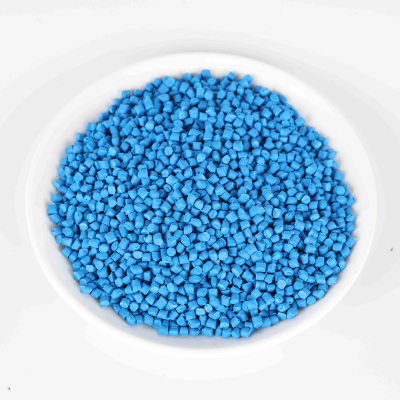

Color: various colors

Carrier: PE ;

Application: plastic products ;

Melting:105℃ ;

Temperature resistance: 300℃

Application: film, pipe, sheet, injection

Pigment contents: customized

Product Specifications

Product name | Red Color masterbatch |

Appearance | 3*3mm round granule, bright and smooth surface |

Appearance | granules |

Granule diameter | 2.5*3.5mm |

Application ratio | 3-4% |

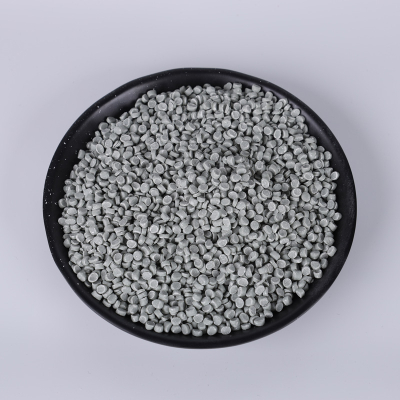

Carbon black concentration | 40% |

Carbon black content | 30% |

Carbon black content | 45% |

Carbon type | N330/N326 |

Carrier | PE |

Chromatic aberration ΔE | ≤0.5 |

Coloring Strength | 120-130% |

Content of carbon black | 40% |

Density | 1.22g/cm3 |

Product Application

Packaging: Red is widely used in food and beverage packaging, pharmaceutical packaging, and cosmetics packaging for its visual appeal and to create attention-grabbing designs.

Consumer Goods: Items such as toys, household appliances, and furniture often utilize red color masterbatch for an eye-catching, aesthetic finish.

Automotive: Automotive parts, such as interior trims, car panels, and custom parts, often use red masterbatches for both aesthetic appeal and brand recognition.

Agricultural Films: Red pigments are used in agricultural films, especially for covering crops where specific wavelengths of light are needed for optimal growth conditions.

Textiles & Nonwoven Fabrics: Red color masterbatch can be used in synthetic fabrics, nonwoven materials, and synthetic fibers.

Industrial Applications: Red masterbatch can also be used in items like pipes, fittings, and other industrial components where red serves as a color identifier or is part of the functional design.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

![Red Color Masterbatch Red Color Masterbatch]()

Company Profile

Jinan Oke Plastics Co., Ltd. is a specialized manufacturer engaged in the R&D, production, and sales of plastic masterbatches, pigments, and additives. Our diverse product range includes black, white, color, functional, and filling masterbatches, widely applied in injection molding, extrusion, film blowing, and coating for materials such as PE, PP, PC, HIPS, and ABS.

With five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, our annual output exceeds 20,000 tons of masterbatches and 3,000 tons of pigments. Supported by a skilled R&D team, cutting-edge production facilities, and advanced color-matching systems, we offer tailored color solutions and comprehensive technical support.

Adhering to international quality standards, our products are exported to Europe, America, Southeast Asia, the Middle East, and South America, earning a strong reputation for excellence, innovation, and customer satisfaction.

![Red Color Masterbatch Red Color Masterbatch]()

Why choose us?

We have advanced production technology, constant innovation.

We promise that our product has passed through rigorous test, the quality can be guaranteed and reliable.

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

We will do our best for the customer as long as you choosing us.

We promise to solve all the problems during trading process.

We promise our quality and the products will be approved by your side.