LDPE White Plastic Masterbatch

Excellent Whiteness and Opacity: Provides consistent whiteness and opacity, often using Titanium Dioxide (TiO₂) as the main pigment.

Good Dispersion: The masterbatch ensures uniform distribution of the white pigment throughout the LDPE product.

Low Processing Temperature: Suitable for processing at lower temperatures compared to other materials like HDPE.

UV Stability (Optional): Some formulations may include UV stabilizers to enhance the product’s ability to withstand exposure to sunlight without degrading.

Enhanced Processability: Designed to work well in extrusion, blow molding, and injection molding processes typically used for LDPE.

Product Introduction

LDPE (Low-Density Polyethylene) white plastic masterbatch is a concentrated mixture of pigments and additives dispersed in a carrier resin, typically designed for use with LDPE materials. This white masterbatch is used to impart a bright, opaque white color to LDPE-based products and may also include other additives for improved performance in various applications.

Characters

Materials:>Pigment, Carrier

Titanium Dioxide Content:70%

Moisture Content:0.15%

Color:white

Carrier:PE / PP

MFI(g/10min):< 48 Micrometre

Application:Film blowing, Injection molding, Blister etc.

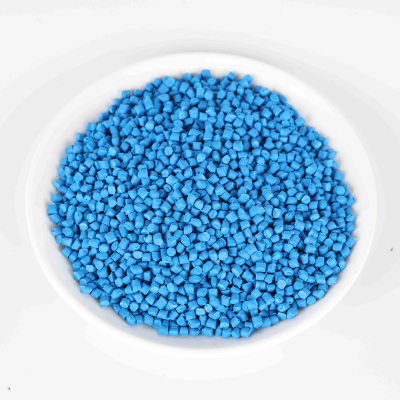

Granual size:2.5mm

Density:0.96g/ Cubic Centimeter

Product Specifications

Product name | LDPE white plastic masterbatch |

Content | 10%-50% |

Carrier | PE/PP/EVA/PVC |

Application | PE/PP/ABS/PVC |

MFI(g/10min) | 0.1-80 (Can be customized) |

Melting Point(℃) | 130-170 |

Density(g/m3) | 1.2-1.8 |

Moisture Content(%) | ≤0.15 |

Grain Diameter(mm) | 1.8-3.8 |

Package | 25kgs plastic compound bag, 5kg vacuum package |

Add Ratio | Recommend to add 2%-5% |

Product Application

Packaging: Used for producing packaging films, bags, and containers. LDPE is often used in flexible packaging and white plastic bags.

Consumer Goods: Used for manufacturing a wide range of consumer products, including toys, medical devices, and household items.

Films and Sheets: Often used in the production of clear or opaque films for protective applications or liners.

Agricultural Products: Applied in the production of agricultural films that need to reflect sunlight or provide some degree of opacity.

Packaging&Storage:

1). All packaging options can be customized.

2). Paper-plastic composite bag.

3). Inner packing: plastic bags; Outer packing: high-quality, moisture-proof bags.

4). Net weight: 25kg per bag.

25kg per bag, packed in paper-plastic composite bags.

Store in a cool, dry place away from direct sunlight.

Company Profile

Jinan Oke Plastics Co., Ltd. is a leading enterprise specializing in the R&D, manufacturing, and sales of plastic masterbatches, pigments, and additives. Our comprehensive product portfolio includes black, white, color, functional, and filling masterbatches, widely applied in injection molding, extrusion, film blowing, and coating processes for materials such as PE, PP, PC, HIPS, and ABS.

Equipped with five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, we boast an annual production capacity exceeding 20,000 tons of masterbatches and 3,000 tons of pigments. Supported by a highly skilled R&D team, state-of-the-art production facilities, and advanced color-matching technology, we deliver customized color solutions and comprehensive technical support.

Committed to international quality standards, our products are exported to Europe, America, Southeast Asia, the Middle East, and South America, earning a strong reputation for excellence, innovation, and customer satisfaction.

FAQ

Q1: Do you provide free product samples?

A: Absolutely! Please share your specific requirements, and we will prepare a customized sample for you.

Q2: What are the shipping terms?

A: FOB Qingdao is our standard, but we can accommodate other shipping terms as well.

Q3: What payment methods do you accept?

A: We accept T/T, L/C, and Western Union.

Q4: What types of plastics are compatible with your masterbatch?

A: Our masterbatch is perfectly suited for PE, PP, PC, ABS, PET, HIPS, GPPS, PA, PMMA, AS, POM, PU, and TPE.

Q5: What are your specialty products?

A: Our top products include transparent filler masterbatch (NaSO₄/BaSO₄/Talc filler masterbatch).