Coloring Process of Color Masterbatch

The coloring process of color masterbatch is a systematic procedure that combines color theory, materials science, and practical production techniques. Below are the key steps and technical points in the color matching process for masterbatches:

1. Fundamental Principles

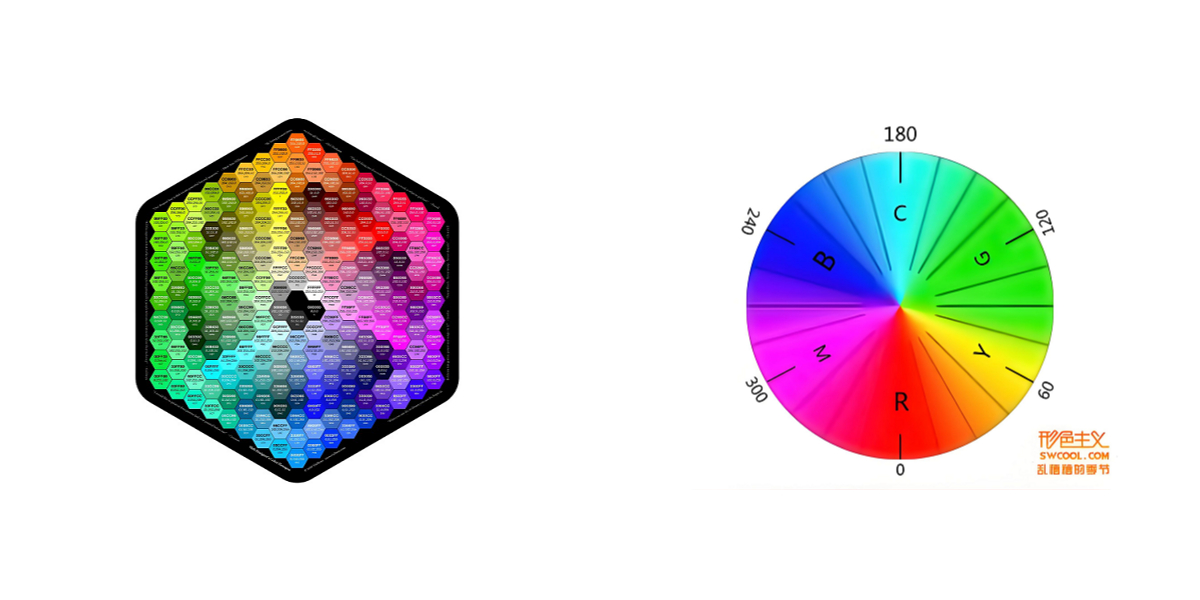

The coloring of masterbatches is based on the subtractive color mixing principle (CMY/K model), achieved by combining different ratios of pigments or dyes. Key considerations include:

● Pigment properties: Hue, tinting strength, heat resistance, dispersibility, etc.

● Base resin compatibility: Affinity with pigments, processing temperature, etc.

● End-use requirements: Weather resistance, migration resistance, food contact safety, etc.

2. Color Matching Process Flow

(1)Color Standard Definition

● Obtain customer requirements (Pantone codes, physical samples, etc.)

● Measure standard samples using a spectrophotometer (L*a*b* values)

● Clarify application conditions (indoor/outdoor, food contact, etc.)

(2)Formulation Design

● Pigment selection:

ºOrganic pigments (high chroma, lower weather resistance)

ºInorganic pigments (good weather resistance, lower saturation)

ºSpecial effect pigments (pearlescent, metallic, etc.)

● Carrier resin matching:

ºMust match the base polymer (PP, PE, ABS, etc.)

●Additives:

ºDispersants (improve pigment dispersion)

ºStabilizers (prevent degradation during processing)

(3) Lab-Scale Testing

● Prepare small batches using a twin-screw extruder or internal mixer

● Color evaluation:

ºVisual comparison (under standard light sources)

ºInstrumental measurement (ΔE < 1 is acceptable)

● Performance testing:

ºMelt flow index (MFI)

ºMigration resistance

(4) Production Scale-Up

● Process parameter control:

ºTemperature (typically 180–250°C)

ºScrew speed (200–400 rpm)

ºFeeding ratio (masterbatch usually contains 15–40% pigment)

● Key control points:

ºPre-dispersion of pigments

ºMelt filtration (typically 80–120 mesh)

3. Key Technical Points

(1) Color Matching Technology

● Computer color matching (CCM) systems:

ºAutomatically calculate approximate formulations from databases

ºCan reduce trial-and-error attempts by over 30%

● Metamerism control:

ºEnsures color consistency under different light sources

(2) Dispersion Technology

● Three-roll milling: For high-viscosity systems

● High-speed mixing: Typically 2000–3000 rpm

● Surface treatment: Silane/titanate coupling agents

(3) Batch-to-Batch Consistency Control

● Raw material inspection (control pigment particle size D50)

● Tight processing window control (±5°C)

● Retain samples from each batch for comparison

4. Common Issues & Solutions

Problem | Possible Cause | Solution |

Color deviation | Pigment batch variation | Establish strict raw material standards |

Streaking | Poor dispersion | Increase dispersant dosage |

Migration | Low pigment molecular weight | Switch to higher-MW pigments |

Poor heat stability | Low pigment thermal resistance | Use heat-stable pigments |

5. Latest Industry Trends

● AI-assisted color matching: Optimizing formulations with machine learning

● Eco-friendly pigments: Heavy-metal-free, PAHs-free alternatives

● Multifunctional masterbatches: Combined color + flame retardant/antistatic properties