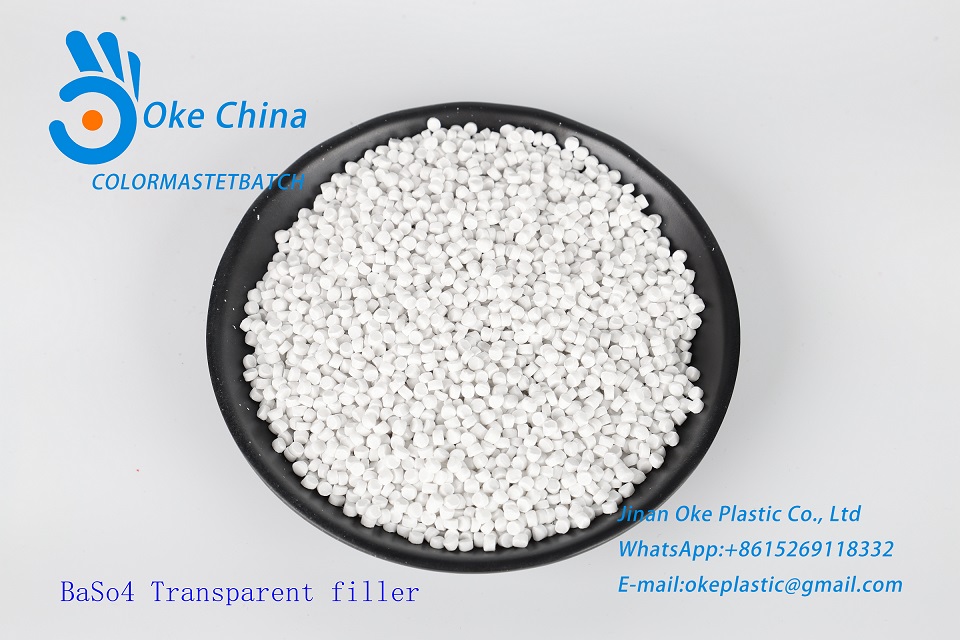

Application of Barium Sulfate in Masterbatch

Barium sulfate (BaSO₄) is widely used in masterbatch due to its unique physical and chemical properties, providing multiple functional enhancements:

1. Filling and Volume Expansion

Cost Reduction: As an inert inorganic filler, barium sulfate can partially replace expensive pigments or resins, reducing production costs while maintaining product performance.

Increased Volume: Its high density (4.5 g/cm³) allows for significant weight and volume increase with minimal addition, making it suitable for applications requiring higher density.

2. Improved Dispersion

Uniform Distribution: Fine barium sulfate particles (especially nano-sized) act as carriers, promoting even pigment dispersion in the resin matrix and reducing agglomeration for consistent coloration.

Enhanced Stability: Its chemical inertness prevents decomposition during high-temperature processing, minimizing color variation in masterbatch production.

3. Optical Property Adjustment

Enhanced Opacity: High refractive index (~1.64) provides excellent covering power, ideal for opaque white or light-colored products.

Gloss Control: Adjusting particle size (e.g., ultrafine powder) allows customization of surface gloss, from matte to high-gloss finishes.

4. Mechanical Performance Enhancement

Increased Rigidity: Barium sulfate improves hardness and flexural modulus, making it suitable for engineering plastics.

Dimensional Stability: Its low thermal expansion coefficient reduces shrinkage and warpage, particularly beneficial in injection molding.

5. Weather and Chemical Resistance

Anti-Aging: UV and acid/alkali resistance extend the lifespan of outdoor products (e.g., automotive parts, construction materials).

Corrosion Resistance: Suitable for packaging or industrial components exposed to chemicals.

6. Environmental and Safety Benefits

Non-Toxic Alternative: Precipitated barium sulfate can replace heavy metal-based pigments, complying with RoHS and REACH regulations for food-contact or children’s products.

7. Special Functional Applications

Flame Retardant Synergy: When combined with flame retardants, it slows combustion and reduces smoke density.

Radiation Shielding: High density offers limited X-ray shielding for medical or nuclear industry masterbatches.

Key Considerations

Surface Treatment: Silane or titanate coupling agents are often used to improve compatibility with organic resins.

Particle Size Selection: Common grades (1250–3000 mesh) are used for general masterbatches, while nano-sized particles balance transparency and mechanical properties.

Dosage: Typically 10–40% of the formulation; excessive amounts may affect melt flow.

Typical Applications

PVC Profiles: Enhances outdoor weatherability and whiteness.

PP Automotive Parts: Improves dimensional stability and reduces shrinkage.

PE Films: Adjusts light transmittance and haze.

Engineering Plastics (PA, PBT): Boosts mechanical strength and surface finish.

Through optimized formulation, barium sulfate enables a balance of functionality (e.g., antimicrobial, conductive) and cost-effectiveness, making it a key component in multifunctional masterbatches.