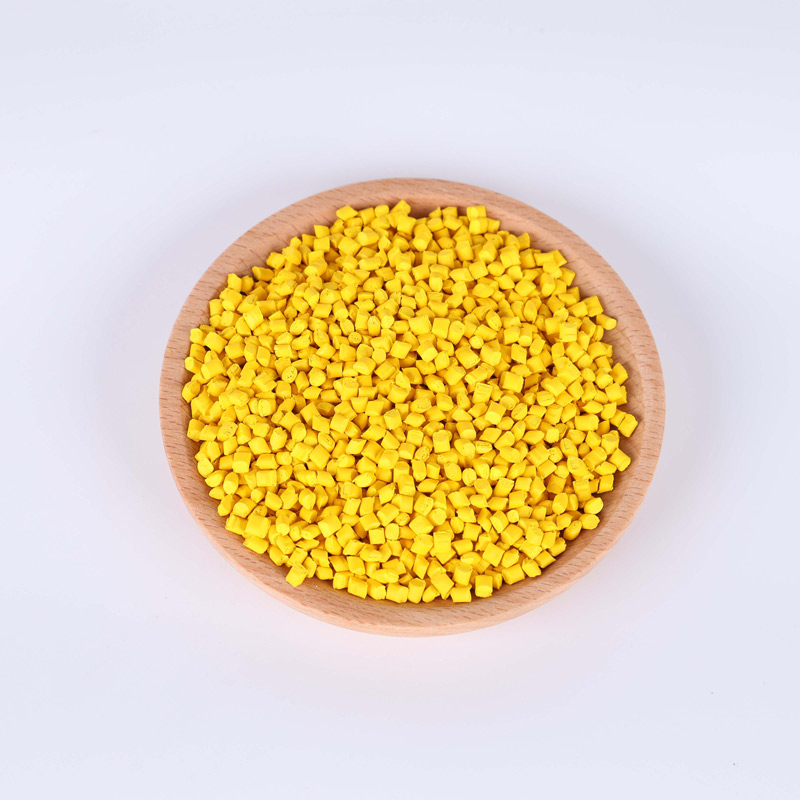

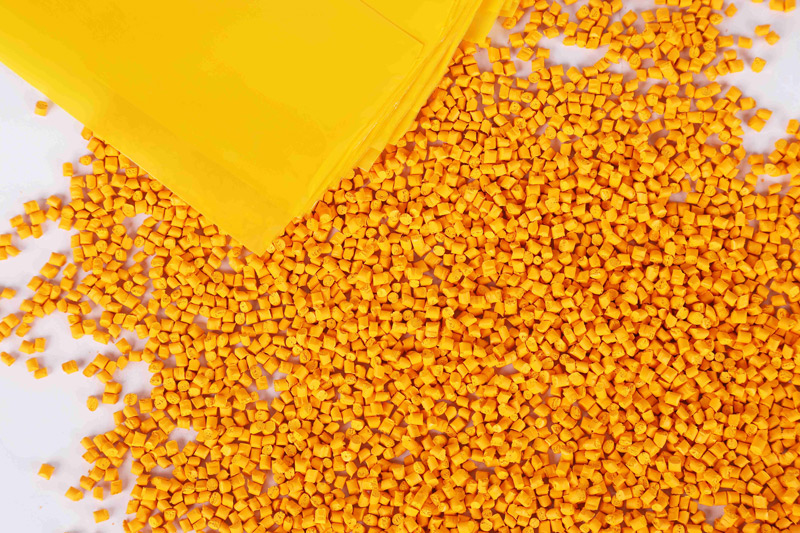

Yellow Color Masterbatch

Consistent Coloration: Ensures uniform color distribution in the final product, enhancing appearance.

Ease of Use: Can be easily mixed with base polymers, simplifying the manufacturing process.

Cost-Effective: Reduces the need for additional coloring agents, thus lowering overall production costs.

Enhanced Processing Characteristics: Provides better flow and processing during manufacturing.

UV Stability: Many formulations offer resistance to UV light, preventing color fading over time.

Compatibility: Suitable for various resin types, making it versatile for different applications.

Improved Aesthetics: Adds vibrancy and visual appeal to products, making them more marketable.

Product Introduction

Yellow Color Masterbatch is a concentrated mix of pigments and polymers utilized to give a yellow hue to plastic products during manufacturing. It's widely used in applications such as packaging, automotive parts, and consumer goods to ensure consistent coloration and enhance the aesthetic appeal of the products.

Characters

Suitable for plastic varieties: PP/PE

Reference ratio: 100/1-3

Light fastness: 7 (grade)

Carrier: PP / PE

Level: General

Active ingredient content: according to customer requirements

Color: various colors

Carrier: PE ;

Application: plastic products ;

Melting:105℃ ;

Temperature resistance: 300℃

Application: film, pipe, sheet, injection

Pigment contents: customized

Product Specifications

Product name | Yellow Color masterbatch |

Appearance | 3*3mm round granule, bright and smooth surface |

Appearance | granules |

Granule diameter | 2.5*3.5mm |

Application ratio | 3-4% |

Carbon black concentration | 40% |

Carbon black content | 30% |

Carbon black content | 45% |

Carbon type | N330/N326 |

Carrier | PE |

Chromatic aberration ΔE | ≤0.5 |

Coloring Strength | 120-130% |

Content of carbon black | 40% |

Density | 1.22g/cm3 |

Product Application

1. Plastic Products: Widely used for coloring various plastic products, including plastic containers, packaging materials, construction materials, automotive parts, electronic and electrical enclosures, etc.

2. Process Compatibility: Compatible with multiple plastic processing techniques such as injection molding, film blowing, blow molding, and extrusion, suitable for various plastic materials like PE, PP, PS, ABS, etc.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

Company Profile

Jinan Oke Plastics Co., Ltd. is a premier manufacturer specializing in the research, development, production, and distribution of plastic masterbatches, pigments, and additives. Our diverse product lineup includes black, white, color, functional, and filling masterbatches, widely applied in injection molding, extrusion, film blowing, and coating for materials such as PE, PP, PC, HIPS, and ABS.

With five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, our annual production capacity surpasses 20,000 tons of masterbatches and 3,000 tons of pigments. Supported by an expert R&D team, cutting-edge production facilities, and advanced color-matching technology, we offer customized color solutions and comprehensive technical assistance.

Committed to international quality standards, our products are exported to markets across Europe, America, Southeast Asia, the Middle East, and South America, earning widespread recognition for quality, innovation, and customer satisfaction.

Why choose us?

We employ cutting-edge production technology and foster continuous innovation.

Every product undergoes strict quality testing to ensure reliability and durability.

Our production and testing equipment meet modern industry standards.

With premium raw materials, advanced machinery, and meticulous procedures, we ensure top performance.

High productivity and fast order fulfillment are our strengths.

Our R&D department is at the forefront of the industry.

We have robust production capacity and ensure rapid delivery.

Our products combine superior quality with competitive pricing.

Our experienced marketing team provides expert guidance.

A skilled design team tailors solutions to customer needs.

We pride ourselves on exceptional after-sales service.

Choosing us means gaining a reliable and committed partner.

We promise to handle any issues that arise during transactions efficiently.

Our products are guaranteed to meet and exceed your expectations.