Blow Molding Masterbatch

High Pigment Load:Ensures consistent, deep black color for aesthetic and quality purposes.

Excellent Dispersion:Prevents streaking or clumping by ensuring even pigment distribution.

UV Resistance:Provides UV protection, preventing degradation and fading in outdoor conditions.

Processing Stability:Designed for smooth flow during high-pressure extrusion and inflation, preventing clogging.

Compatibility with Resins:Compatible with various resins like HDPE, LDPE, PET, PP, and more.

Product Introduction

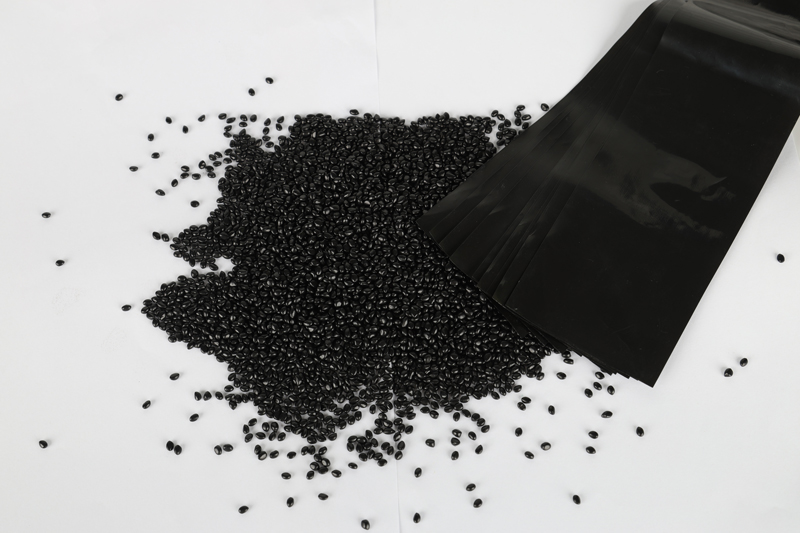

Blown molding grade black masterbatch is a specially designed concentrate used in the production of plastic products via the blown molding process, where plastic is melted and inflated into a bubble to form hollow parts like bottles, containers, and other products. This masterbatch is specifically formulated to provide consistent black coloration, along with other properties that are essential for the unique requirements of blown molding.

Characters

Color:Black

Customer order:Accept

Carbon Black Content: 20%-50%

Filler:CaCO3 or None.

Carrier:PP PE.

Application:ABS/PS/PC/PP/PE.

Usage:2%-5%.

Packing:Paper plastic composite bag.

Product Specifications

Product name | Blown Molding Grade Black Masterbatch |

Carbon Black Content | 20%-50% |

Carrier | PP/PE(Can be customized) |

Application | PE/PP/LLDPE/HDPE/LDPE/ABS/PS/PA/PVC/EVA |

MFI(g/10min) | 0.1-80(or as customers, requirment) |

Melting Point(℃) | 120-150 |

Density(g/cm3) | 1.2-1.7 |

Moisture Content(less than %) | 0.15 |

Grain Diameter(mm) | 1.8-3.8 |

Package | 25kgs Paper Bag |

Technical Specification | SGS Certificate |

Light Fastness | Grade 4-8 |

Heat Resistance | ≥4 |

Migration Resistance | ≥4 |

Filler | CaCO3 or None |

Product Application

1)Packaging:

Bottles and Containers: Plastic bottles, jars, and containers used for beverages, chemicals, cosmetics, and personal care products are commonly made with black masterbatch. Black masterbatch not only provides aesthetic value but also helps protect sensitive contents from UV light (e.g., UV-sensitive liquids, chemicals, or pharmaceuticals).

Food Packaging: Certain food packaging, particularly opaque or light-blocking containers (such as juice bottles or dairy packaging), may use black masterbatch to maintain freshness and prevent light degradation.

Cosmetic and Personal Care Packaging: Packaging for beauty products, such as jars, tubes, and caps, is often produced using black masterbatch to provide a premium, sleek look.

2)Automotive Components:

Interior Parts: Black masterbatch is used in the production of molded automotive interior parts like dashboards, door panels, armrests, and other trim parts. It helps with the visual appeal while providing additional benefits like UV protection and scratch resistance.

Exterior Parts: Automotive exterior parts like bumpers, grilles, and side mirrors may also use black masterbatch for color uniformity and UV stability.

Housings for Electrical Components: Black masterbatch is used for automotive wiring and connectors, as well as other electrical components that require consistent color and UV resistance.

3)Agricultural Films and Products:

Mulch Films: Agricultural films, particularly those used in mulching applications, often use black masterbatch. The black color helps prevent weed growth by blocking sunlight while also regulating soil temperature.

Greenhouse Films: Black masterbatch is used in films and sheets used in greenhouses to provide shade, temperature control, and protection for crops.

4)Consumer Goods:

Toys: Some molded toys and play equipment may use black masterbatch to achieve consistent color and durability.

Furniture and Appliances: Outdoor furniture and parts for appliances, such as housings for fans, air conditioners, or even vacuum cleaners, can be produced using black masterbatch to provide a sleek look and enhance the product's longevity.

5)Industrial Applications:

Storage Containers: Large storage bins, drums, and containers often incorporate black masterbatch for a uniform color and UV protection, which extends the life of the product, especially for outdoor storage.

Pipes and Fittings: Black masterbatch can be used in the production of pipes and fittings (e.g., for irrigation or construction) where UV resistance is important to prevent degradation under sunlight.

6)Medical and Pharmaceutical Packaging:

Light-Protective Packaging: Some light-sensitive pharmaceuticals or medical products (e.g., certain medications, syringes, or IV bags) are packaged using materials produced with black masterbatch to block UV light and preserve the integrity of the contents.

7)Consumer Electronics:

Electronics Housings: For certain types of molded housings in electronic devices, black masterbatch provides an appealing look and resistance to wear and tear.

Packaging&Storage:

1).All the packing can be customized.

2).Paper plastic composite bag.

3).Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4).Net weight is 25kg/bag.

25kg/bag, paper-plastic compound bags

Keep it in a cool,dry place,without sunshine.

Company Profile

Jinan Oke Plastics Co., Ltd. is a leading company specializing in the research, development, production, and sales of plastic masterbatches, pigments, and additives. Our extensive product range includes black, white, color, functional, and filling masterbatches, which are widely used in injection molding, extrusion, film blowing, and coating applications for materials such as PE, PP, PC, HIPS, and ABS.

With five automated color masterbatch lines, three black masterbatch lines, two white masterbatch lines, and two pigment production lines, our annual production capacity exceeds 20,000 tons of masterbatches and 3,000 tons of pigments. Supported by a professional R&D team, state-of-the-art production facilities, and advanced color matching systems, we offer tailored color solutions and comprehensive technical support.

Our products adhere to international standards and are exported worldwide, including to Europe, America, Southeast Asia, the Middle East, and South America, earning a reputation for superior quality, innovation, and customer satisfaction.

FAQ

Q1:Do we provide free sample of the products

A: Of course,please feel free to tell me your specific require,and then we will make the corresponding customized sample to you .

Q2: What is the shipping terms?

A:FOB Qingdao,others accepted

Q3: How about your payment?

A:T/T,L/C,western union.

Q4:What kind of plastic do our masterbatch fit?

A:Perfectlysuit:PE/PP/PC/ABS/PET/HIPS/GPPS/PA/PMMA/AS/POM/PU/TPE.

Q5: What’s your advantage products?

A:Transparent filler masterbatch(NaSO4/BaSO4/Talc filler masterbatch)