The Role of Plastic Additives in Manufacturing

Plastics are used in every aspect of our daily lives, from packaging materials and medical devices to household items and automotive parts. Plastics are so versatile, thanks in large part to the ability to add a variety of additives to enhance their properties to meet the needs of specific applications.

At OKe, we understand how important it is to understand how additives can change and optimize plastic products, allowing us to meet the diverse needs of industries such as medical, personal care and food and beverage. In this article, we will explore the types of plastic additives and their impact on plastic properties. Understanding these additives is key to manufacturing high-quality, durable and critical products for different industries.

What are plastic additives?

Plastic additives are materials added during the plastic processing process to improve or change certain properties of plastics. These additives can change the physical, mechanical and cosmetic properties of plastics to make them more suitable for specific uses. In this way, we can ensure that the performance and durability of the final product are optimal. Additives affect various aspects of plastics, such as flexibility, strength, color and resistance to environmental factors, making them indispensable in modern manufacturing.

Types of Plastic Additives

· -Stabilizers

· -UV Stabilizers

· -Heat Stabilizers

· Plasticizers

· Flame Retardants

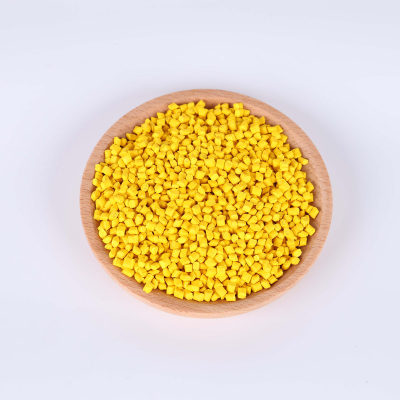

· Colorants

· Fillers

· Antioxidants

How Additives Enhance Plastic Performance Additives play a key role in enhancing the performance of plastics:

• Enhanced durability: Stabilizers and antioxidants protect plastics from environmental factors, ensuring long-term performance in products such as medical devices and automotive parts.

• Improved flexibility: Plasticizers make plastics more flexible and easier to process, which is critical for products such as tubing, seals and packaging.

• Improved safety: Flame retardants enhance the fire resistance of plastics, making them safer in key applications such as electronics and household goods.

• Aesthetic appeal: Colorants can customize plastics for branding and design purposes, while also providing additional features such as UV resistance.

• Cost-effectiveness: Fillers reduce overall manufacturing costs by reducing the amount of expensive resins used, while also improving the mechanical properties of the material.

At OKe, we understand that plastic additives are critical to optimizing product performance across a wide range of industries. Whether enhancing durability, improving flexibility or ensuring safety, additives allow us to meet the specific needs of our customers. By carefully selecting the right combination of additives, we ensure that the plastics we produce reach the highest performance levels, whether used in medical devices, personal care products or food and beverages.