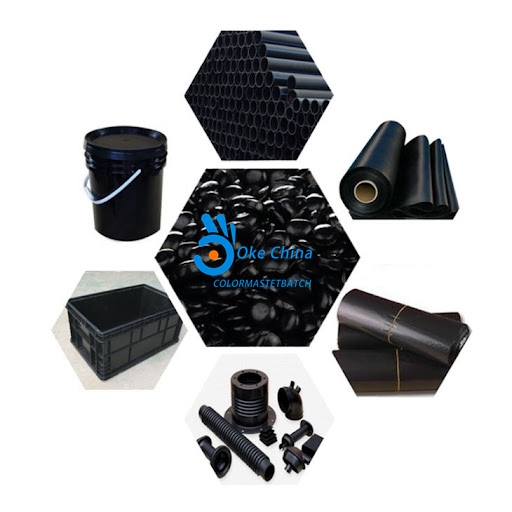

Black Masterbatch

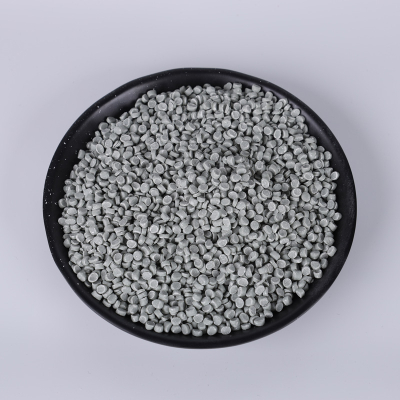

Black masterbatch is a functional color concentrate made from a high proportion of carbon black or organic pigments, carrier resins, and dispersants. It is primarily used for coloring plastics, rubber, and other materials. Below is a detailed introduction to black masterbatch:

1. Main Components

Pigments: Carbon black (most common, 20%-50% content), organic black pigments (e.g., aniline black).

Carrier Resin: Polymer compatible with the base material (e.g., PE, PP, ABS, PS).

Dispersants: Ensure uniform pigment dispersion and prevent agglomeration.

Additives: Antioxidants, lubricants, etc., to enhance processing stability.

2. Key Features

High Coloring Power: Achieves deep black coloration with minimal addition.

Excellent Dispersion: Pre-dispersed formulation reduces surface streaks or spots.

Eco-Friendly: Dust-free, safer than direct carbon black powder use.

Stability: Heat-resistant, migration-resistant, suitable for various processing conditions.

3. Applications

Plastics: Packaging films, appliance casings, automotive parts, pipes, fibers.

Rubber: Tires, seals, shoe soles.

Special Uses: Conductive carbon black masterbatch (anti-static), UV-shielding masterbatch.

4. Production Process

1. Mixing: Blending carbon black, carrier resin, and additives in precise ratios.

2. Melt Extrusion: High-temperature dispersion via twin-screw extruder.

3. Pelletizing: Cutting cooled extruded strands into uniform granules.

4. Quality Control: Testing color consistency, dispersion, melt flow index, etc.

5. Common Issues & Solutions

Poor Dispersion: Optimize carrier resin or increase dispersant content.

Color Deviation: Control carbon black concentration and processing temperature.

Uneven Conductivity: Use high-structure carbon black (e.g., acetylene black).

6. Market & Selection Guide

Carbon Black Types: Furnace black (common), channel black (higher blackness).

Resin Compatibility: Match carrier to base material (e.g., PP masterbatch for polypropylene products).

Environmental Compliance: Meets RoHS, REACH, and other regulatory standards.

For specific application examples or technical parameters (e.g., temperature resistance, conductivity), feel free to specify your requirements!