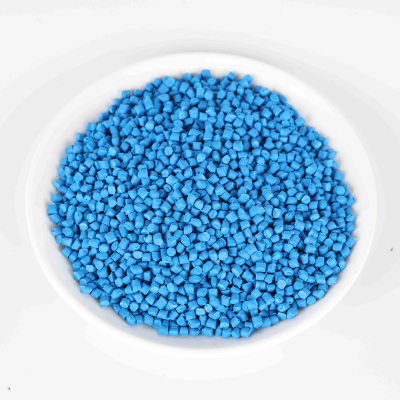

PE CaCO₃ blown film filling

1. Significantly reduce production costs

✅ High filling ratio: The filling ratio of CaCO₃ can reach 20%-85%, which greatly reduces the cost of raw materials.

✅ Reduce the amount of resin: Under the premise of ensuring basic performance, reduce the use of pure plastic, especially suitable for mass production products such as packaging film, injection molded parts, and pipes.

✅ High cost performance: Compared with other mineral fillers (such as talcum powder and mica), CaCO₃ has a wide source, stable price, and better economy.

2. Improve plastic processing performance

✅ Improve melt fluidity: CaCO₃ particles can reduce melt viscosity, make film blowing, injection molding, and extrusion smoother, and reduce energy consumption.

✅ Reduce equipment wear: CaCO₃ has moderate hardness and less wear on screws and molds than fillers such as glass fiber.

✅ Stable processing technology: The optimized masterbatch formula can reduce problems such as film bubble jitter and extrusion fluctuations, and improve production efficiency.

Advantages of CaCO₃ Filler Masterbatch

Calcium carbonate filler masterbatch is a functional plastic modification material produced by compounding high-purity calcium carbonate with carrier resin through specialized processes, widely used in the plastics processing industry.

1. Composition

● Core filler: Ultrafine heavy/light calcium carbonate (particle size 1-10μm)

● Carrier resin: HDPE/LLDPE/PP, etc. (15-40% content)

● Surface treatment agent: Titanate/aluminate coupling agent (1-3%)

● Processing aids: Polyethylene wax/stearate lubricants (0.5-2%)

2. Key Performance Parameters

| Parameter | Typical Range | Test Standard |

|---|---|---|

| CaCO₃ content | 50-80wt% | GB/T 2914 |

| Melt flow rate | 2-15g/10min | GB/T 3682 |

| Density | 1.5-2.0g/cm³ | GB/T 1033 |

| Whiteness | ≥92% | GB/T 5950 |

3. Processing Characteristics

● Dispersion: Twin-screw extrusion process ensures uniform CaCO₃ dispersion (D50≤5μm)

● Compatibility: Surface modification improves filler-resin interface bonding strength by >30%

● Processing window: Suitable temperature range 160-220℃, with excellent resin compatibility

4. Application Benefits

● Cost control: Reduces raw material costs by 30-50% maximum

Performance enhancement:

Increases flexural modulus by 20-40%

Raises heat deflection temperature by 5-15℃

Improves product dimensional stability

● Processing advantages:

Reduces extruder torque by 10-20%

Increases production line speed by 15-30%

5. Typical Applications

● Packaging: BOPP films (10-20% addition), PE bags (20-30%)

● Building materials: PP-R pipes (15-25%), PVC profiles (10-15%)

● Consumer goods: Injection-molded household products (20-40%)