What Is The Requirement For Using The Masterbatch?

What Is The Requirement For Using The Masterbatch?

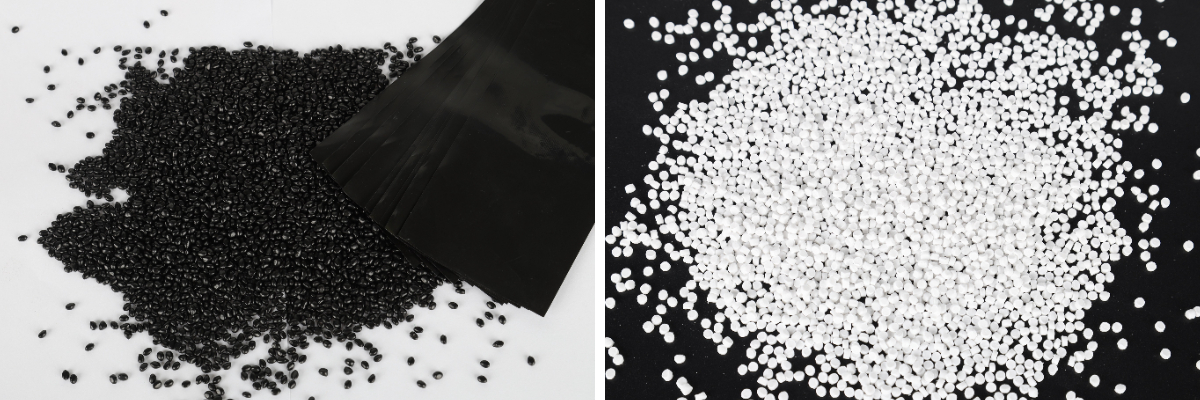

The use of masterbatch in manufacturing processes involves specific requirements to ensure effective incorporation into the base polymer and achieve the desired product characteristics. These requirements include material compatibility, processing conditions, equipment, and adherence to quality standards. Below is a detailed breakdown:

1. Material Compatibility

· Base Polymer Compatibility: Ensure the carrier resin in the masterbatch is compatible with the base polymer to allow uniform mixing and prevent defects.

· Pigment/Additive Compatibility: Confirm that the pigments or additives in the masterbatch do not chemically react with or degrade the base polymer.

· Moisture Sensitivity: Address moisture sensitivity if the masterbatch contains hydrophilic materials (e.g., pre-drying if necessary).

2. Dosage and Ratio

· Recommended Dosage: Typically, the masterbatch constitutes 1–5% of the total weight of the polymer, but this may vary depending on the required effect (color strength, additive functionality).

· Precision in Measurement: Accurate dosing equipment is required to avoid under- or over-use, which could affect product quality or production costs.

3. Processing Equipment

· Mixing Equipment: Use equipment capable of evenly blending the masterbatch with the base polymer (e.g., extruders, high-speed mixers).

· Extrusion Lines: Ensure the extrusion equipment is clean and free of residues that might contaminate the masterbatch-polymer blend.

· Injection Molding Machines: For injection molding, ensure that the screw and barrel design support homogeneous mixing.

4. Pre-Processing Requirements

· Drying: If moisture content is a concern, pre-dry the masterbatch as per the supplier’s recommendations to prevent quality issues such as voids or poor dispersion.

· Temperature Sensitivity: Ensure the masterbatch is stored and used within its temperature tolerance to avoid degradation.

5. Processing Conditions

· Temperature Settings: Match the processing temperature to both the masterbatch and the base polymer’s thermal stability limits.

· Shear Rate: Adjust the shear rate to ensure proper dispersion of the masterbatch without causing degradation.

· Cycle Time: Optimize the production cycle time to achieve uniform blending and avoid defects.

6. Quality Control

· Testing: Perform batch tests to evaluate properties such as color consistency, mechanical strength, and other desired characteristics in the final product.

· Inspection: Ensure there are no contaminants or clumps in the masterbatch before use.

· Certification: Use masterbatch that meets industry standards (e.g., FDA compliance for food-grade applications, UV stability for outdoor use).

7. Environmental and Safety Compliance

· Material Safety Data Sheet (MSDS): Review the MSDS for handling, storage, and disposal instructions.

· Regulatory Compliance: Verify that the masterbatch complies with environmental and safety regulations relevant to the application.

8. Storage Requirements

· Environment: Store in a cool, dry, and well-ventilated area.

· Packaging: Keep the packaging sealed when not in use to prevent contamination and moisture absorption.

· Shelf Life: Use the masterbatch within its recommended shelf life to maintain effectiveness.

Meeting these requirements ensures that the masterbatch is effectively utilized, achieving consistent quality and performance in the final product while minimizing waste and production issues.