What Is The Masterbatch Is Used?

What Is The Masterbatch Is Used?

Masterbatch is used in the plastics industry to add specific properties, colors, or functionalities to base polymers during the manufacturing process. It is a concentrated mixture of pigments, additives, or fillers that is pre-dispersed in a carrier resin. Masterbatch simplifies the production process by allowing easy customization of plastic products without directly handling raw pigments or additives.

Uses of Masterbatch

1. Coloration

· Adds vibrant or uniform color to plastic products.

· Eliminates the need to mix raw pigments during processing.

· Examples:

White Masterbatch: Imparts opacity and brightness.

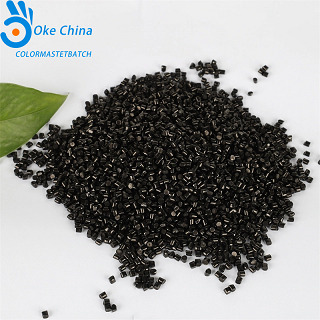

Black Masterbatch: Provides high jetness and UV protection.

Custom Color Masterbatch: Tailored to achieve specific hues or effects.

2. Functional Enhancements

Masterbatch enhances the performance or usability of plastic products by introducing specific properties:

· UV Stabilizers: Protects against degradation from sunlight.

· Antioxidants: Prevents oxidation during processing and use.

· Flame Retardants: Makes plastics resistant to ignition and flame spread.

· Antimicrobials: Inhibits bacterial or fungal growth for hygiene-critical products.

3. Additive Properties

· Slip Agents: Reduces friction between plastic surfaces.

· Anti-Static Additives: Prevents static charge buildup.

· Anti-Fog Masterbatch: Prevents fogging on plastic films in packaging.

· Defoam Masterbatch: Eliminates foam in production processes.

4. Filler Enhancement

· Reduces production costs by using fillers like calcium carbonate or talc.

· Improves mechanical properties, such as rigidity or thermal resistance.

5. Aesthetic Effects

· Provides special effects like pearlescence, metallic finishes, or transparency.

· Used in packaging, automotive interiors, or decorative applications.

6. Recycling and Sustainability

· Desiccant Masterbatch: Removes moisture from recycled plastics.

· Enhances the quality of products made from recycled materials.

Industries That Use Masterbatch

1.Packaging:

Food containers, stretch films, and shopping bags.

2.Agriculture:

Mulch films, greenhouse coverings, and irrigation pipes.

3.Construction:

Pipes, fittings, sheets, and insulation materials.

4.Automotive:

Interior trims, under-hood components, and exterior parts.

5.Household Goods:

Furniture, appliances, and storage containers.

6.Electrical and Electronics:

Cable sheathing and anti-static components.

Masterbatch is critical for tailoring polymer products to meet specific aesthetic, functional, or environmental requirements. If you need insights on a particular type of masterbatch, let me know!